How do you choose the right thermal bonding nonwoven fabric?

Choosing the wrong nonwoven material is a costly mistake. This confusion leads to product failures and wasted budgets. Let me help you make the right choice from the start.

To choose the right thermal bonding nonwoven, you must match the fiber\'s properties to your product\'s specific needs. Consider factors like temperature resistance, required strength, and softness to select the correct raw material for your application.

Knowing the selection criteria is the first step. But to apply it effectively, you need a solid understanding of the material itself. What is it made of? What are your options? Many of our customers come to us with these questions. Let\'s break down the fundamentals so you can choose your fabric with confidence, just like an expert would.

What exactly is a thermal bonding nonwoven fabric?

The term "thermal bonding" can be confusing. This confusion makes it hard to specify the exact material you need. I will give you a clear and simple definition.

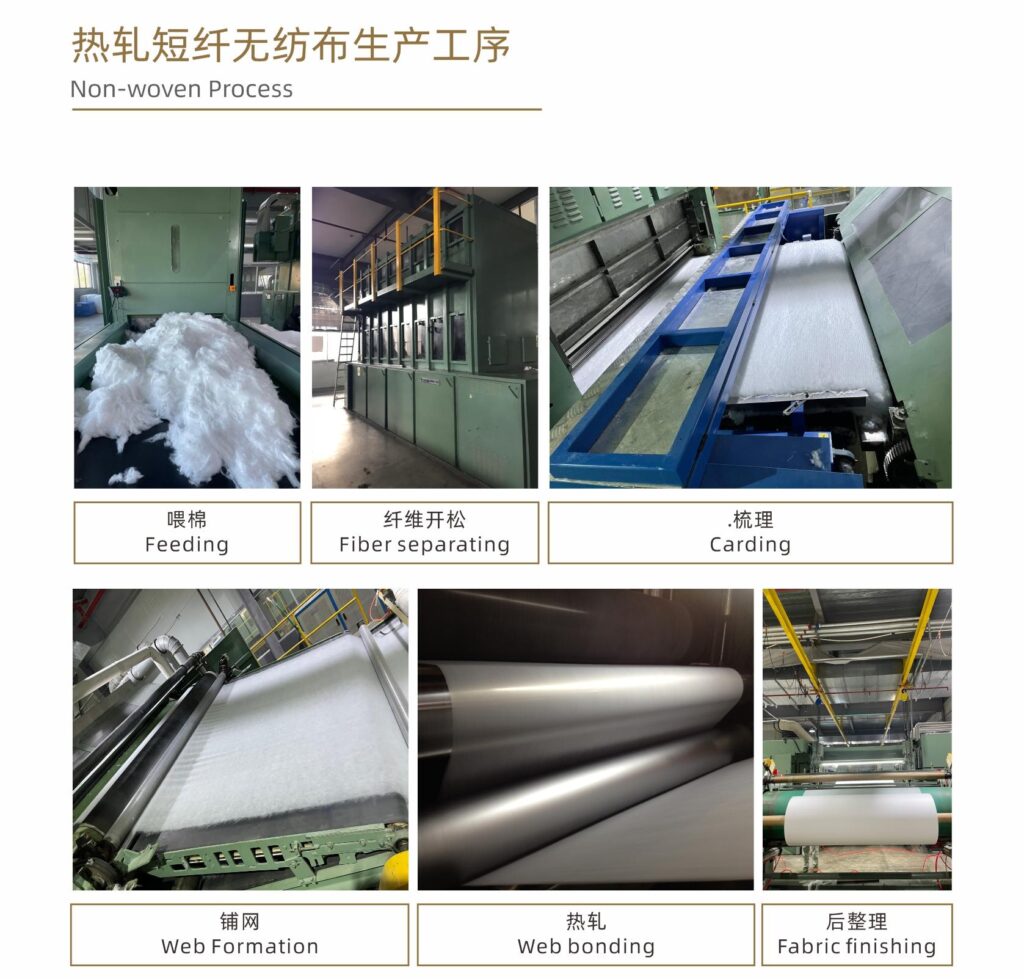

A thermal bonding nonwoven fabric is a material made from short staple fibers that are bonded together using heat. Instead of weaving or knitting, the fibers are fused, creating a uniform, sheet-like structure.

In my 20-plus years leading Golden Lily, I’ve seen that simple definitions are the most powerful. Think of it this way: spunbond nonwovens are like spaghetti, made from long, continuous strands. Thermal bonded nonwovens are more like a granola bar, made from short pieces (the fibers) held together by a binder (the melted binder fibers). This simple difference is key. Because it\'s made from short fibers, the process gives us incredible control over the final product\'s uniformity and texture. It\'s not as strong as spunbond, but its consistency is perfect for applications like filtration and packaging, where every square inch needs to perform the same way. The real choice comes down to picking the right ingredients for that "granola bar."

What types of fibers are used in thermal bonding?

The huge variety of fibers can be overwhelming. Choosing the wrong one can cause your product to fail in its real-world application. Let\'s simplify the options for you.

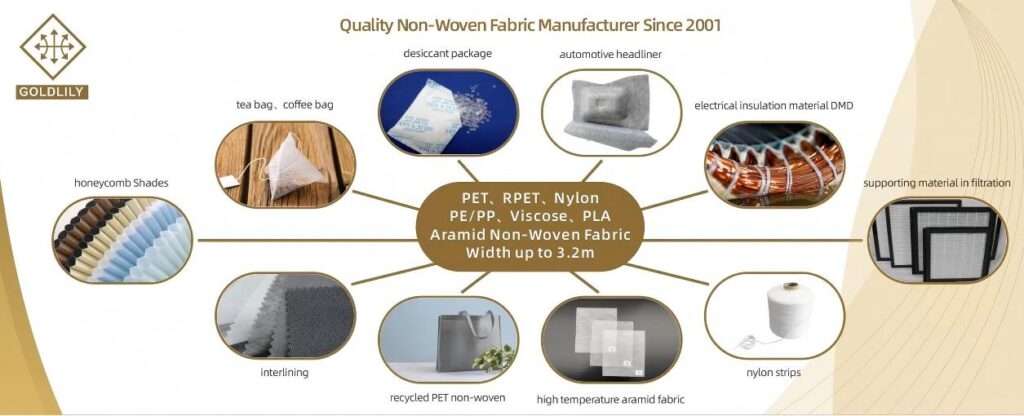

The most common fibers are polyester, nylon, ES fiber, PLA, and viscose. Each has unique properties. Your choice depends entirely on your product\'s final use and processing requirements, such as heat resistance or strength.

This is the most critical decision you will make. I always tell my customers that the final fabric is defined by the raw fibers we start with. You cannot make a high-temperature filter from a fiber that melts easily. You cannot make a soft hygiene product from a stiff, abrasive fiber. The first question we ask at Golden Lily is always, "What will you use this for?" The answer tells us everything we need to know to recommend the right material. Thinking about the end-use first saves a lot of time and prevents costly errors down the line.

Matching Fiber to Application

To help you choose, let\'s look at the most common fibers and what they are good for. You must consider their performance Across different categories.

| --- | ||||||

|---|---|---|---|---|---|---|

| Polyester (PET) | Strong, stable, good heat resistance, cost-effective. | DMD insulation materials, interlinings. | ||||

| Nylon (PA) | Very strong, excellent heat and abrasion resistance. | interlinings, nylon trips. | ||||

| ES Fiber (PE/PET) | Soft, bonds at low temperatures. | Soft hygiene products (diaper topsheets), desiccant package,tea bag. | ||||

| CO-PET | Low melting point, acts as a binder. | Honeycomb shades,filtration. | ||||

| PLA | Biodegradable, made from plant resources. | Eco-friendly packaging, disposable food-grade items. | ||||

| Viscose | Very absorbent, soft, biodegradable. | Wipes, medical pads, applications needing high absorbency. | ||||

| Aramid | Extremely strong, flame-resistant. | Protective apparel, high-temperature industrial filtration. |

How to Think About Your Choice

When a client comes to us, we guide them with a simple checklist:

- Heat Resistance: What is the maximum temperature the fabric will face?

- Chemical Resistance: Will it be exposed to acids or alkalis?

- Strength: Does it need to withstand pulling or tearing?

- Feel: Should it be soft and drapable or stiff and rigid?

- Breathability: Does air or liquid need to pass through it?

By answering these questions, we can narrow down the potential fibers and create a fabric that performs perfectly.

Conclusion

To choose the right thermal bonded fabric, match the raw fiber\'s properties to your product\'s real-world needs. Know your requirements for temperature, strength, and softness to succeed.

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.