How to bond non-woven fabric?

Trying to join non-woven fabric but sewing just damages it? Using the wrong glue can create a weak, messy bond that fails under pressure and looks unprofessional.

Non-woven fabrics are bonded using three main methods: thermal bonding (heat sealing), ultrasonic bonding (vibrations), or adhesive bonding (glue). The best method depends on the fabric's material and what the final product will be used for.

As a manufacturer of non-woven fabrics, I'm not just focused on making the fabric itself. I also have to consider how our customers will use it. A big part of that is how they will seam, seal, or attach it to other materials. The way you join two pieces of non-woven fabric is just as important as the fabric itself. A bad seam can ruin a great material. Let's look at the most common ways this is done in industry and where each method shines.

How does thermal bonding work?

You need to create a secure, clean seal for a packaging product. You're worried that glues could contaminate the contents and that sewing would create holes and compromise the barrier.

Thermal bonding, or heat sealing, uses direct heat and pressure to melt and fuse thermoplastic fibers together. It creates a strong, clean bond without any additional materials, making it perfect for sealing food-safe packaging.

This is a method we know very well at Golden Lily. Our staple fiber thermal bonding process is designed to create fabrics that are perfect for this exact purpose. We make our fabrics using special bicomponent fibers, often called ES fibers. These fibers have a core with a high melting point for strength, and an outer sheath with a much lower melting point.

When a client uses our fabric to make something like a tea bag or a desiccant pouch, they use a heat-sealing machine. This machine applies precise heat and pressure to the edges of the fabric. The heat is just enough to melt the outer sheath of the fibers on the surface. When the pressure is released and the fabric cools, the melted sheaths fuse together, creating a permanent, clean-welded seam. There's no glue, no thread, no mess. It's a fast, efficient, and sanitary process, which is why it's so widely used for packaging food, coffee, and moisture-absorbing products. The fabric itself is engineered to be perfectly compatible with this bonding method.

What is ultrasonic bonding?

You need to bond a non-woven fabric that is sensitive to direct heat. You're concerned that a heat sealer would scorch or melt through the material entirely.

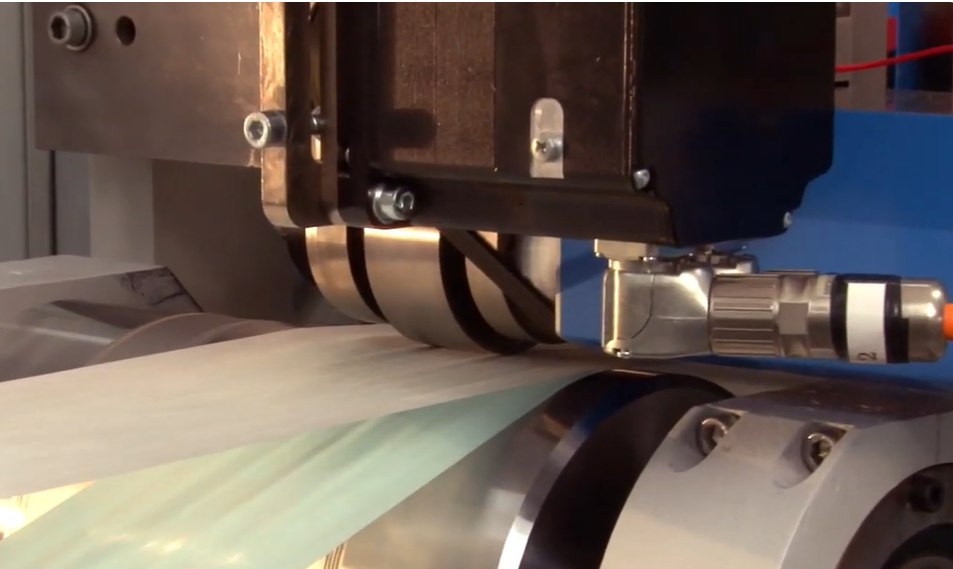

Ultrasonic bonding uses high-frequency vibrations to generate localized heat between two layers of fabric. The rapid friction creates a molecular bond by melting and fusing the fibers together almost instantly without applying external heat.

Think of ultrasonic bonding1 as creating heat from the inside out. It's a very clever process. A machine uses a vibrating tool, called a horn, that presses the fabric against a solid base, called an anvil. The horn vibrates incredibly fast—usually over 20,000 times per second. This intense vibration creates friction between the layers of fabric. The friction, in turn, generates enough heat to melt the thermoplastic fibers2 (like polyester or polypropylene) right at the point of contact.

Why Choose Ultrasonic?

This method is fantastic for several reasons:

- Precision and Speed: It's extremely fast and can create very intricate and precise bond patterns. It's great for detailed work on medical gowns or face masks.

- No External Heat: Since the heat is generated internally, there is no risk of scorching the surrounding material. This is ideal for delicate or thin non-wovens.

- Cleanliness: Like thermal bonding, it creates a clean weld with no adhesives or consumables.

The main requirement is that the fabric must contain a sufficient amount of thermoplastic material to melt and fuse. It's an excellent alternative to heat sealing, especially for applications where precision and a delicate touch are needed.

When should you use adhesives?

You're trying to bond a non-woven fabric that doesn't contain thermoplastic fibers. Neither heat sealing nor ultrasonic bonding will work because there's nothing in the fabric that can melt.

Adhesives should be used when bonding non-woven fabrics made from natural fibers like cotton or viscose, or for joining a non-woven to a completely different material. Adhesive bonding offers versatility when thermal methods are not an option.

Sometimes, thermal and ultrasonic methods are simply not possible. This is often the case when a fabric doesn't have the right kind of plastic content to melt and fuse. For example, if you have a non-woven made of 100% viscose or cotton, it will burn before it melts. In these situations, adhesives are the only solution.

The process involves applying a specialized glue to one or both surfaces and then pressing them together. The type of adhesive is critical and depends on the specific application. There are several ways to apply it:

- Spray Adhesives: A fine mist of glue is applied for wide area coverage.

- Hot Melt Adhesives: A solid glue is heated to a liquid, applied, and then forms a strong bond as it cools. This is very common in constructing hygiene products like diapers.

- Web Adhesives: A thin, web-like sheet of adhesive is placed between the layers before being activated by heat and pressure.

While effective, using adhesives introduces another material into the product, which can affect its recyclability and may not be suitable for food-contact or medical applications. It's a versatile but more complex solution, best reserved for when other cleaner bonding methods won't work.

Conclusion

Bonding non-wovens is done through heat sealing, ultrasonic vibrations, or adhesives. The choice depends on the fabric's plastic content and the need for a clean, strong, and contamination-free seal.

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.