Is non-woven fabric good for face masks?

You wear a mask all day, but it's itchy and uncomfortable. You wonder if this is really the best material, feeling irritated by the friction and unsure about its overall effectiveness.

Yes, non-woven fabric is not just good—it's the ideal material for face masks. It's used in distinct layers to provide filtration, structure, and comfort, making masks safe, breathable, and skin-friendly when properly designed.

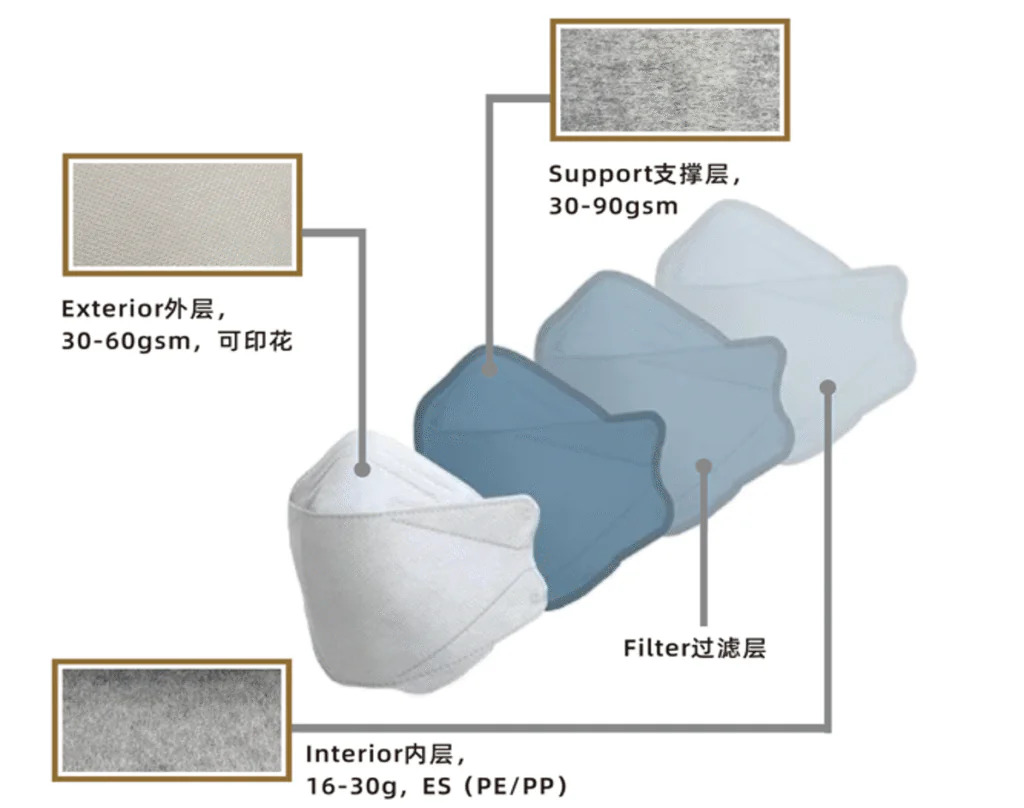

The modern disposable face mask looks simple, but it’s actually a sophisticated piece of engineering. And at the heart of that engineering is non-woven fabric. Before the pandemic, most people never thought about what their masks were made of. But now, we all know that the material matters. It's not just one type of fabric; it's a carefully assembled sandwich of different non-woven layers, each with a very specific job to do. From blocking droplets to feeling soft against your skin, non-wovens make it all possible.

Why do masks use different non-woven layers?

Your mask feels rough against your skin, but you know it needs to be effective against germs. You feel stuck choosing between comfort and protection, wishing you didn't have to sacrifice one for the other.

Masks use a 3-layer system to deliver both comfort and protection. A soft non-woven inner layer rests against your skin, a high-efficiency meltblown middle layer filters particles, and a durable outer layer provides a protective barrier.

The secret to a good mask is the synergy between its layers, a structure often called "SMS1" (Spunbond-Meltblown-Spunbond). Each layer is a non-woven fabric, but they are made differently to perform unique roles. I think of it as building a high-performance team where every player has a specialty.

The Inner Layer: The Comfort Specialist

This is the layer that touches your face all day, so its primary job is comfort. We make materials specifically for this purpose, like our PE/PP bicomponent non-woven. It's incredibly smooth and soft, which dramatically reduces friction and skin irritation. It's also designed to be breathable and to manage moisture, making the mask much more pleasant to wear for long periods.

The Middle Layer: The Filtration Hero

This is the most critical layer for protection. It’s almost always made from meltblown non-woven fabric. Meltblown is a web of extremely fine, randomly laid fibers that create a tortuous path for air to pass through. This structure physically traps microscopic particles. Furthermore, it's electrostatically charged to actively attract and capture even the smallest airborne contaminants, acting like a powerful magnet for germs.

The Outer Layer: The Protective Shield

The outer layer is the mask's first line of defense. It's typically a spunbond non-woven that is strong and water-resistant. Its job is to repel splashes, sprays, and large droplets, and to provide structural integrity for the entire mask.

What are the different materials used for mask fabrics?

You see masks made of different materials, from standard blue to fancy colors. You're not sure if they are all equally safe or if some are just a marketing gimmick.

While polypropylene (PP) is the industry standard for its excellent balance of properties, other safe materials are now common. These include polyester (PET) for structure and bicomponent fibers (like PE/PP) for superior softness on skin-contact layers.

During the pandemic, the demand for masks skyrocketed, which pushed manufacturers like us to innovate and utilize a wider range of materials. While they might look different, they are all chosen for specific performance characteristics.

The most traditional and widely used material is polypropylene (PP). It's a fantastic all-rounder. It's used to make both the spunbond outer layers and the meltblown filter layer. It is hydrophobic (repels water), has good strength, is cost-effective, and can be electrostatically charged, making it the workhorse of the mask industry.

However, we've found that other materials can enhance performance in specific layers. For example, our bicomponent (PE/PP) non-woven is a game-changer for the inner layer. The PE (polyethylene) component has a lower melting point and a smoother, waxier feel than PP. By engineering it into the surface of the fabric, we create a material that is noticeably softer and gentler on the skin. This directly addresses the common complaint of face irritation. For other applications, polyester (PET) might be blended in to add stiffness or thermal stability to a mask's structure. All these materials are polymers that are proven to be safe for this type of application.

Are there eco-friendly non-woven options for masks?

You rely on disposable masks for safety but feel guilty about the mountain of plastic waste they create. You find yourself wishing there was a more sustainable and responsible option.

Yes, eco-friendly options are emerging. Polylactic Acid (PLA) non-woven fabric is a biodegradable material made from plant-based resources like corn starch. It can be used to create effective and more sustainable mask layers.

The environmental impact of disposable masks is a serious concern for me and for many of our customers. This has driven a lot of research and development in our field. The most promising solution right now is Polylactic Acid (PLA). Unlike traditional plastics derived from petroleum, PLA is a bioplastic made from fermented plant starch.

We can process PLA fibers using our existing thermal bonding lines to create non-woven fabrics suitable for every layer of a mask. A PLA spunbond fabric can be used for the inner and outer layers, and PLA can even be meltblown to create a filter layer. While PLA meltblown currently faces challenges in holding an electrostatic charge as long as PP, the technology is rapidly improving. The biggest advantage is its end-of-life. Under the right industrial composting conditions, a PLA mask can biodegrade back into natural components, drastically reducing its long-term environmental footprint compared to a traditional PP mask that will persist for centuries. It's a very exciting area of development for us.

Conclusion

Non-woven fabric is the perfect material for masks. Its ability to be engineered into distinct layers for comfort, filtration, and protection makes masks both safe and comfortable to wear.

-

Understanding SMS can enhance your knowledge of mask quality and effectiveness, crucial for health and safety. ↩

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.