Is nylon a non-woven?

The terms "nylon" and "non-woven" are often used together, which can be confusing. You might wonder if they are the same thing, or if one is a type of the other.

No, nylon is a material, not a fabric structure. Nylon is a strong, synthetic polymer. A non-woven is a type of fabric made by bonding fibers together instead of weaving or knitting. Therefore, you can have a "nylon non-woven," which is a non-woven fabric made from nylon fibers.

When I first started in the chemical fiber industry, this was one of the first things I learned. It's a fundamental concept that is very important. It is like the difference between flour and a cake. One is the ingredient, and the other is the final product. Understanding this helps explain why certain fabrics have such unique and valuable properties, especially in demanding applications like high-quality clothing.

What is the difference between nylon and non-woven?

Fabric specifications can be confusing. You see nylon and non-woven on the same spec sheet and wonder what it means. Getting this wrong can lead you to choose an unsuitable fabric.

The difference is simple: nylon is the raw material (the ingredient), while non-woven is the construction method (the recipe). Nylon provides inherent properties like strength and softness, while the non-woven process determines the fabric's final form and texture.

Let's break this down further. Think about building a house. You need materials like wood, bricks, and steel. You also need a method of construction, like framing or masonry.

-

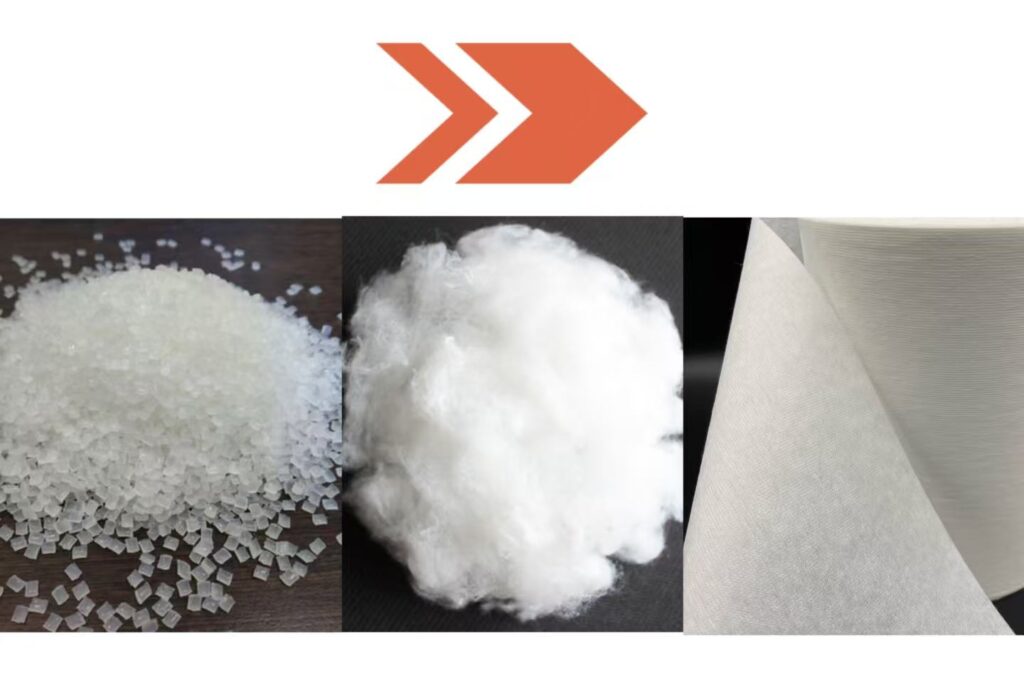

Nylon is the Material: In our world, nylon is like a premium building material. It's a type of polymer known officially as polyamide. As a material, it is famous for its exceptional strength, abrasion resistance, and elasticity. We start with nylon chips, which are melted and extruded to create fine, continuous filaments or short staple fibers. These are the basic building blocks.

-

Non-Woven is the Method: This is how we assemble the building blocks. Instead of the traditional, highly ordered methods of weaving (interlacing yarns in a grid) or knitting (interlooping yarns), the non-woven method creates a web of fibers directly. These fibers are then bonded together using heat, chemicals, or pressure. It's a faster, more direct way to make a sheet of fabric.

So, when we talk about a "nylon non-woven," we are describing a fabric sheet that was built using the non-woven method from nylon fibers.

| Component | Definition | Analogy |

|---|---|---|

| Nylon | A synthetic polymer (polyamide) | The raw ingredient (e.g., flour) |

| Non-Woven | A fabric made by bonding fibers | The finished product (e.g., a cake) |

How is nylon non-woven fabric made?

You know you need a fabric with nylon's properties. But how do we turn those raw fibers into a soft, consistent sheet without weaving them? The process seems complex and hard to control.

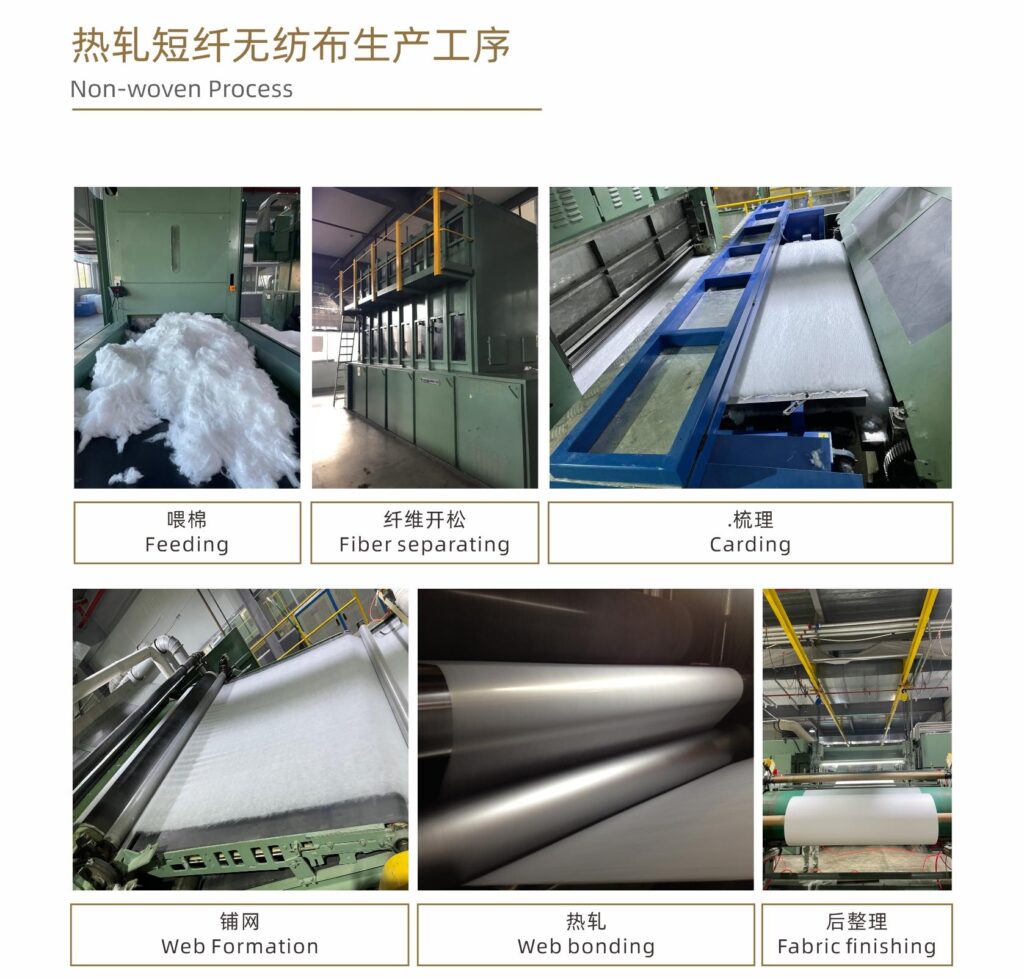

Nylon non-woven is made using a dry-laid thermal bonding process. First, nylon staple fibers are combed into a uniform web. Then, this web passes through heated rollers, which melt and fuse the fibers together into a cohesive fabric without using any chemical glues.

The process is very precise and is what gives the final fabric its signature feel and performance. My company has been perfecting this for years, especially for customers in the garment industry who demand perfection.

The Key Steps

- Opening and Carding: We start with bales of high-quality nylon staple fibers. These are short fibers, maybe an inch or two long. The first step is to open these compressed bales and gently comb the fibers using a machine called a card. The carding machine has large rollers covered in fine wire teeth that separate and align the fibers into a thin, fluffy, uniform sheet called a web.

- Thermal Bonding: This web is very delicate. To give it strength, we pass it through a set of large, heated, and smooth calendar rollers. The combination of high temperature and pressure melts the nylon fibers just enough at their contact points. As they cool, they fuse together, locking the web into a stable, durable fabric. This method is clean and efficient, and because it uses no binders or glues, the final fabric retains the pure properties of nylon.

This process gives us incredible control over the final product's weight, thickness, and softness, which is critical for making high-end products.

What are the key properties of nylon non-woven fabric?

Many fabrics are strong, but they feel stiff or rough. Other fabrics are soft, but they tear easily or don't hold their shape after stretching. Finding a material that does everything well is a huge challenge.

Nylon non-woven fabric is exceptionally soft, highly durable, and has excellent stretch and recovery. Its high abrasion resistance and lightweight feel make it the ideal material for high-quality garment interlinings, providing structure without sacrificing comfort or movement.

When a customer comes to me looking for an interlining for a premium jacket or high-end sportswear, I often recommend our nylon non-woven. An interlining is the hidden layer of fabric that gives a garment its shape and structure. The end customer will never see it, but they will absolutely feel it.

Why Nylon Excels Here

- Softness and Drape: The thermal bonding process creates a very soft and pliable fabric. Unlike some stiff polyester non-wovens, nylon non-woven drapes beautifully with the main fabric. It supports the garment's shape without making it feel like cardboard.

- High Elongation: Nylon is naturally elastic. This means the interlining can stretch with the outer fabric and the wearer's movements and then return to its original shape. This is essential for comfort in activewear or the shoulders of a well-tailored suit.

- Wear Resistance: Nylon is one of the toughest fibers there is. An interlining made from it will not break down or thin out from friction or repeated washing. It ensures the garment keeps its intended shape for its entire life.

Because of this unique combination of softness, stretch, and strength, nylon non-woven is a top choice for brands that cannot compromise on quality.

Conclusion

Nylon is the high-performance material, and non-woven is the method used to make it into a fabric. The resulting nylon non-woven is soft, strong, and stretchy for premium applications.

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.