What are non-woven wipes?

You use disposable wipes every day, but do you know what they are? Using the wrong type can mean a rough texture on sensitive skin or a wipe that falls apart mid-use.

Non-woven wipes are cleaning cloths made from fibers bonded together, not woven like traditional fabric. This direct bonding allows for specific properties like high absorbency and softness, typically using either a spunlace or a thermally-bonded manufacturing process.

When people think of wet wipes, they usually picture one specific type. But the technology behind them is more diverse than most realize. The method used to make the base fabric determines everything about the final wipe, from its thickness and softness to how it feels on your skin. As a manufacturer specializing in certain non-woven processes, I see how these technical differences create very different products for consumers. Understanding this is key to choosing the right material for any application.

How are most common wet wipes made?

You assume all wet wipes are the same, but the thick, cloth-like ones feel very different from others. This difference in texture and bulk comes directly from the manufacturing method.

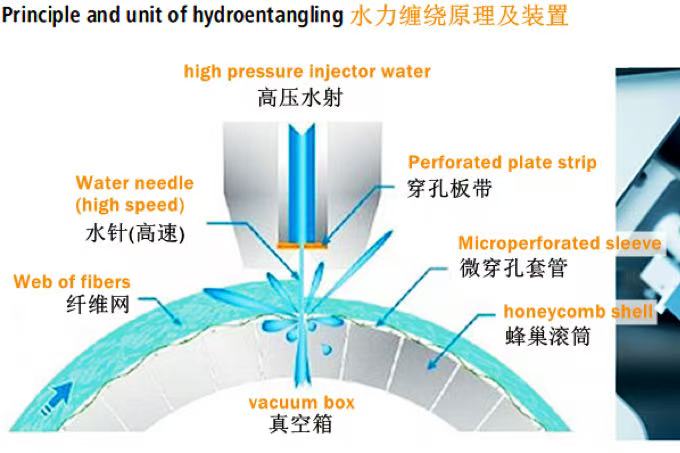

Most common wet wipes are made using the spunlace method. This process uses high-pressure jets of water to tangle fibers together, creating a material that is thick, soft, and feels very similar to traditional cloth.

The spunlace process is a marvel of engineering. It's technically a form of mechanical bonding, but instead of needles, it uses water. First, a web of fibers is laid out. This web often includes a blend of viscose, for its incredible absorbency, and polyester, for strength. Then, this web passes under rows of jets that shoot out water at extremely high pressures. This intense force causes the individual fibers to knot and entangle with each other, locking them into a strong, cohesive fabric.

The final product is remarkably soft and has excellent drape. Because it uses no binders or glues, it's very pure. This combination of strength, softness, and absorbency makes it the go-to material for many standard consumer products, including baby wipes and facial cleansing cloths. It produces a premium, textile-like feel that consumers have come to expect from leading brands. Spunlace is an excellent technology, but it’s not the only way to make a great wipe.

Are there softer and thinner alternatives to spunlace wipes?

You want to create a portable wipe product, but standard spunlace material is too bulky. It makes your final packaging too large for a pocket or a small purse.

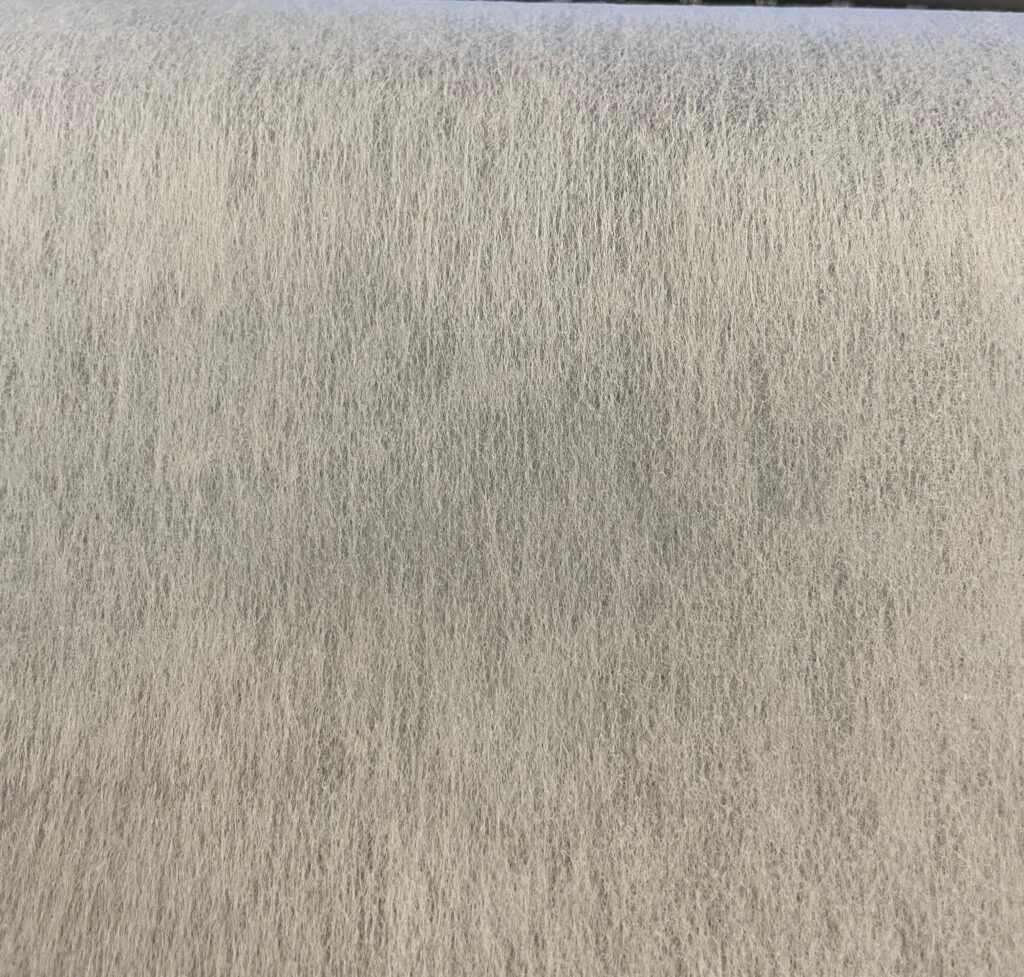

Yes, an excellent alternative is a thermally-bonded non-woven made from bicomponent fibers. This process creates a wipe that is exceptionally thin and soft, making it perfect for compact, on-the-go packaging where space is limited.

This is an area where my company, Golden Lily, specializes. While spunlace makes a great, thick wipe, our thermal bonding process allows us to create something with a different set of advantages. It all starts with a special type of fiber called a bicomponent staple fiber, often "ES fiber."

The Thermal Bonding Advantage

Here's how we make these thin, soft wipes:

- Special Fibers: We use ES fibers, which have a core of polyester (PET) or polypropylene (PP) for strength, surrounded by an outer sheath of polyethylene (PE). The PE sheath has a lower melting point than the core.

- Carding: We take these short fibers and run them through a carding machine, which acts like a giant, fine-toothed comb. It aligns the fibers into a uniform, fluffy web.

- Hot-Rolling: This web is then passed between large, heated steel rollers. The heat is precisely controlled to melt only the outer PE sheath of the fibers. As it cools, the melted sheath acts like a glue, bonding the fibers together at every point they touch. The inner core remains solid, giving the fabric its strength.

The result is a fabric that is incredibly uniform, soft, and much thinner than a comparable spunlace material. It's a clean, efficient process that creates a product perfect for slim travel packs.

| Feature | Spunlace Wipes | Thermally-Bonded ES Wipes |

|---|---|---|

| Manufacturing | Water jet entanglement | Heat and pressure (hot-rolling) |

| Feel | Thick, soft, cloth-like | Exceptionally thin, very soft, smooth |

| Fibers | Viscose/Polyester Blends | Bicomponent (ES) Staple Fibers |

| Best For | Standard-size packs, baby wipes | Travel packs, facial masks, compact wipes |

Why is a smooth surface important for wipe materials?

Your product is for sensitive skin, and you worry about irritation. A wipe that feels soft in the package can sometimes feel abrasive during actual use, causing redness and discomfort.

A smooth surface is critical because it minimizes friction on the skin. Thermally-bonded ES non-wovens excel here, as the hot-rolling process creates a very flat, even surface without loose fibers, reducing the potential for irritation during cleansing.

This is a subtle but very important point that I often discuss with clients in the hygiene and cosmetics industries. Softness is not just about how fluffy a material feels. It is also about a lack of abrasiveness. While spunlace fabrics are soft, the entangled fiber structure can sometimes have more surface texture.

The thermal bonding process, particularly with the smooth, heated calendars we use, effectively presses the fabric into a very regular and level plane. This creates a surface that glides over the skin with minimal friction. We use this exact material as the skin-contact layer for high-quality face masks for the same reason—it needs to be comfortable against the face for long periods. For a makeup remover wipe or a wipe for sensitive baby skin, this smoothness is a huge advantage. It ensures the wipe cleans effectively without causing stress to the skin, providing a better and more comfortable user experience. It's another example of how controlling the manufacturing process allows us to engineer a material for a very specific, high-value purpose.

Conclusion

Non-woven wipes are versatile cleaning tools made from bonded fibers. The manufacturing method, whether spunlace or thermal bonding, determines if the final product is thick and cloth-like or exceptionally thin and smooth.

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.