What fibers are used in thermal bonding?

Choosing the right fiber for a thermal bonded nonwoven is confusing. If you pick the wrong one, your product could literally fall apart under pressure or heat, wasting time and money.

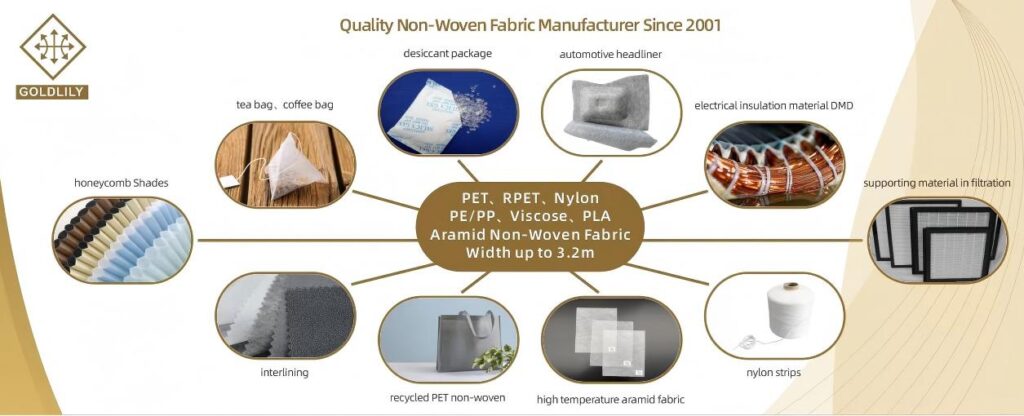

The main fibers used are polyester (PET), polypropylene (PP), and special bicomponent fibers like ES (PE/PET) and CO-PET. The choice depends entirely on the product's required strength, softness, and most importantly, temperature resistance and sealability.

The fiber is the most basic ingredient of a nonwoven fabric. At Golden Lily, we treat it like a chef treats their ingredients. Every property—its thickness, length, and how it reacts to heat—changes the final dish. To pick the right one, we first need to quickly review the "cooking method" itself: thermal bonding.

What is thermal bonded fabric?

The term "thermal bonded" seems simple, but it can be misleading. If you assume it always means the same thing, you might misunderstand a fabric's true capabilities.

Thermal bonded fabric is a nonwoven made by applying heat and pressure to a web of fibers. This process fuses the fibers together, either by melting a special "glue" fiber or by softening the surface of standard fibers to weld them together.

Part of our philosophy is a commitment to professional growth and learning. This starts with understanding the fundamentals of our craft. There are two main ways to use heat in thermal bonding. The first method uses fibers that have two parts, a core and an outer sheath, where the sheath melts at a low temperature to act like a hot-melt glue. The second method uses a single type of fiber and applies very high heat to soften and fuse the fibers where they touch. Mastering both methods allows us to create a huge range of products.

We can compare these two main techniques:

| Bonding Method | How It Works | Common Fiber Type | Resulting Fabric |

|---|---|---|---|

| Sheath/Core Bonding | Uses bicomponent fibers. The low-melt outer sheath melts, bonding the high-melt cores together. | ES Fiber (PE/PET), CO-PET | Soft, flexible, often heat-sealable. |

| Area Bonding | Uses single-component fibers. High heat and pressure soften and fuse the fibers at their contact points. | Standard Polyester (PET) | Smooth, strong, and very stable. |

By choosing the right fiber and the right bonding technique, we can engineer a fabric to meet almost any performance requirement.

What is the difference between the different types of fibres?

You see the codes—PET, PE/PET, CO-PET—but they just look like a jumble of letters. Choosing a fiber based on its name alone is a total gamble for your product's success.

The key difference lies in their structure and melting point. Standard polyester (PET) is a single, high-melt fiber for heat resistance. Bicomponent fibers (like ES or CO-PET) have a low-melt outer sheath that acts as a binder, enabling bonding at lower temperatures.

I believe in building an open and fair system, and that includes sharing knowledge. Helping our partners understand these materials is key to our mutual success. The fiber choice really comes down to one question: Does the product need to withstand high heat, or does it need to be sealed with heat? The answer determines which fiber we use. At Golden Lily, we primarily work with three types of staple fibers for our thermal bonding processes.

Here’s a simple breakdown:

| Fiber Type | Structure | Key Property | When We Use It |

|---|---|---|---|

| Polyester (PET) | Solid, single-component fiber. | High melting point (~260°C). Very stable and strong. | For products that need to resist heat and hold their shape. |

| ES Bicomponent | Sheath/Core (e.g., PE sheath / PET core) | Low-melt sheath (~130°C) bonds the structural cores. | For soft, heat-sealable products like packaging. |

| CO-PET Bicomponent | Sheath/Core (Low-melt PET / Standard PET) | All polyester, but the sheath melts at a lower temperature (~110-180°C). | For products needing polyester's strength plus heat-sealability. |

Think of an ES fiber like a plastic-coated wire. The outer plastic can melt to stick things together, but the inner wire stays strong. This simple difference in fiber structure opens up completely different worlds of application.

What are the different uses of non-woven fabrics of different fibers?

You know the fibers, but you're still not sure which one is right for your product. Matching the fiber's unique properties to the application is the final and most critical step.

High-melt polyester (PET) is used for heat-resistant applications like electrical insulation and honeycomb shades. Low-melt bicomponent fibers (ES, CO-PET) are used for heat-sealable products like tea bags, coffee pods, and certain filter media.

Our goal is to help every member of the Golden Lily family "work happily and live a dignified life." A huge part of this is the pride we take in seeing our materials succeed in the real world. We work closely with our customers, from manufacturers of packaging materials to producers of high-tech composites. This experience has taught us exactly how to pair the right fiber with the right job.

For Strength and Heat Resistance: Polyester (PET)

When a product must be strong, stable, and able to withstand high temperatures, standard high-melt polyester is the only choice. It’s the workhorse for tough industrial and durable goods.

- Electrical Insulation: It's the core material in DMD (Dacron-Mylar-Dacron) insulation because it won't break down from the heat generated by motors and transformers.

- Honeycomb Shades: The fabric must hold crisp pleats for years without sagging. Polyester's incredible dimensional stability makes this possible.

- Apparel Interlinings: It provides structure to collars and cuffs and can withstand hot irons and repeated washing.

For Sealing and Engineered Softness: Bicomponent Fibers

When a product needs to be sealed with heat or requires a softer touch while maintaining strength, we turn to bicomponent fibers.

- Packaging Materials: This is the ideal material for tea bags and coffee filter pods. The low-melt sheath allows for fast, strong heat-sealing on production lines, keeping the contents inside while allowing for infusion.

- Filtration Materials: CO-PET is fantastic for pleated air filtration media. It combines the strength and chemical resistance of polyester with the ability to be thermally bonded into a stable, self-supporting structure without needing messy glues or resins.

Conclusion

The fibers used in thermal bonding determine a fabric's destiny. Standard polyester offers strength and heat resistance, while advanced bicomponent fibers provide softness and the all-important ability to heat-seal.

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.