What is a non-woven roll used for?

You see giant rolls of non-woven fabric in factories and know they are used for many things. But the sheer variety is confusing, making it hard to see the possibilities for your own project.

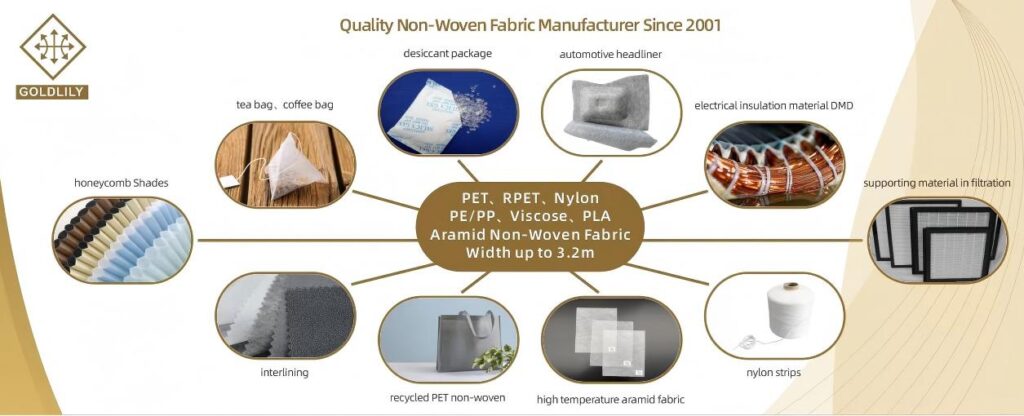

A non-woven roll is a versatile raw material used in countless industries. Its applications range from hygiene products like wipes and masks, to durable goods like garment interlinings, filtration media, packaging, home textiles, and electrical insulation. The specific use is determined by the specific material and manufacturing process.

The COVID-19 pandemic made "non-woven" a household word. Everyone suddenly knew that the material in their face masks, typically a spunbond fabric, was a non-woven. They learned that the material for sanitizing wipes, often a spunlace fabric, was also a non-woven. But this knowledge only scratches the surface. The world of non-wovens is much bigger and more complex than just masks and wipes. The real potential lies in how we can create different materials for vastly different jobs.

How do different non-wovens serve different industries?

You know non-wovens are versatile, but how can one material work for both a filter and a shirt? Choosing the right type for your specific need feels impossible without a guide.

Different non-wovens serve industries through precise engineering. By selecting specific fibers (like polyester or nylon) and bonding methods (like thermal bonding), we create unique properties. A soft, flexible non-woven fits a garment, while a stiff, porous one is ideal for filtration.

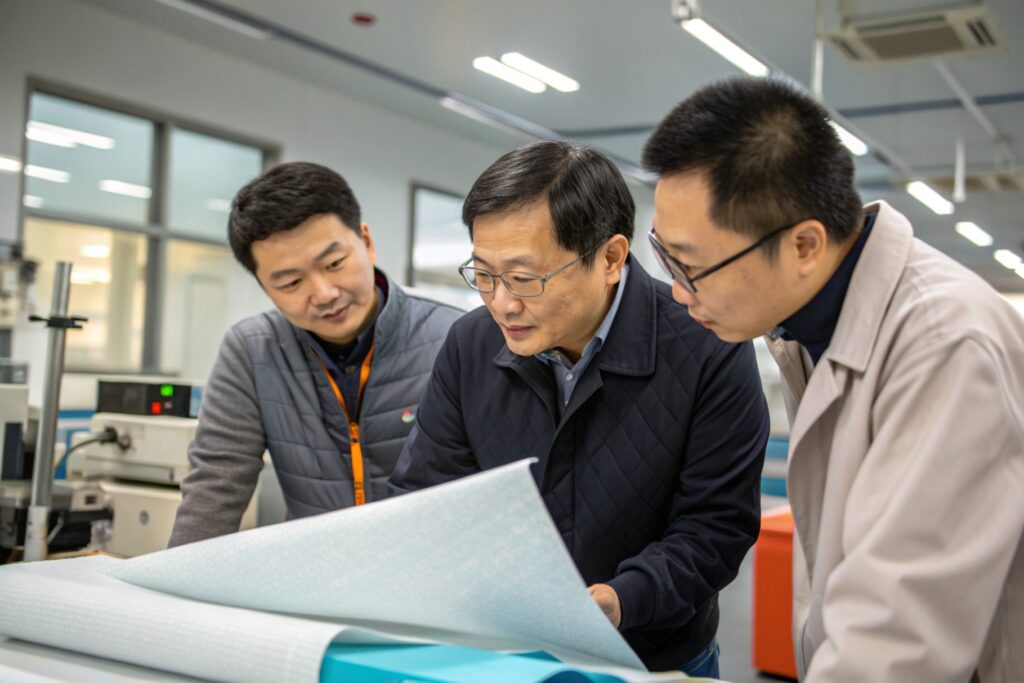

Over the years, my company has expanded from one core area into many different fields. It all started with understanding that no two industries have the exact same needs. My job is to listen to a customer's problem and then build a fabric solution from the ground up, starting with the fiber itself.

Tailoring Fabrics for a Purpose

The uses are incredibly diverse, and each one requires a specific set of properties. Here are some of the main areas we serve:

- Garment Interlinings: This was our first specialty. A high-quality jacket needs structure, but it must remain soft and comfortable. We use polyester or nylon non-wovens that are thermally bonded to provide support without stiffness. The fabric moves with the wearer and holds the garment's shape over time.

- Packaging Materials: For products like tea bags or desiccant pouches, the fabric needs to be strong, porous, and safe for contact with consumables. Our heat-sealable bicomponent non-wovens are perfect for this. They contain no chemical adhesives and meet FDA standards.

- Air Filtration: An air filter needs a support layer to give it strength and structure. We use specific polyester fibers to create a stiff, porous non-woven fabric that holds the delicate filtration media in place without blocking airflow.

- Home Textiles: Think of honeycomb blinds. They require a stiff fabric that can be pleated and hold its shape perfectly, even after thousands of uses. Our heat-resistant polyester non-wovens are engineered for exactly this kind of dimensional stability.

| Industry | Required Property | Our Non-Woven Solution |

|---|---|---|

| Garments | Softness, Drape, Structure | Thermally bonded Polyester/Nylon |

| Packaging | Heat-Sealable, Food-Safe | Bicomponent (ES) Fibers |

| Filtration | Stiffness, Porosity, Strength | Structured Polyester (PET) |

| Home Textiles | High Stiffness, Heat Resistance | Calendered Polyester (PET) |

How are new applications for non-woven fabrics developed?

Your project has a unique material challenge that off-the-shelf fabrics can't solve. You might feel stuck, thinking that a custom solution is too complex or out of reach.

New applications are developed through collaboration. The process starts with a customer's unique need. We then work together to identify the right raw material, sometimes co-developing a new fiber with our suppliers. We create samples, test them, and refine the fabric until it perfectly meets the new demand.

This is the most satisfying part of my job. It is where we move from being a simple supplier to becoming a true partner in innovation. It’s a journey we take with our customers. The process usually follows a clear path, turning a problem into a tangible product.

The Innovation Journey

I remember working with a client in the electrical materials industry. They needed a wrapping material for cables that was thin, incredibly strong, and highly resistant to heat. No standard fabric on the market was quite right.

- Define the Need: We sat down with the client to understand every detail. The material needed excellent impregnation properties for resins, high tensile strength, and minimal shrinkage at high temperatures.

- Material and Fiber Selection: Based on the heat and strength requirements, we knew polyester was the right base material. But we had to find the perfect fiber denier and staple length to achieve the right balance of thinness and strength.

- Collaborate with Suppliers: The ideal fiber wasn't readily available. I worked directly with my fiber suppliers, using my background in chemical fibers to explain the exact polymer characteristics we needed. Together, we developed a modified PET fiber.

- Prototyping and Testing: We took this new fiber and ran it through our thermal bonding lines, adjusting temperature and pressure to create initial samples. The client tested these samples for impregnation and heat resistance.

- Refinement: The first batch was good, but not perfect. It was slightly too stiff. We adjusted our carding and calendering process to create a more flexible fabric without losing strength. After a few rounds of this feedback loop, we had the perfect material.

This process, from a simple conversation to a final product, is what continues to expand the uses of non-woven fabric.

Conclusion

Non-woven rolls are used as a custom-engineered starting point for countless products across many industries, from soft clothing interlinings to strong industrial materials, all developed through collaborative innovation.

Related Articles

Hello world!

Welcome to WordPress. This is your first post. Edit or

How do you choose the right thermal bonding nonwoven fabric?

Choosing the wrong nonwoven material is a costly mistake. This

How non-woven fabric become water resistance

Non-woven fabrics are naturally quite absorbent due to their structure

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.