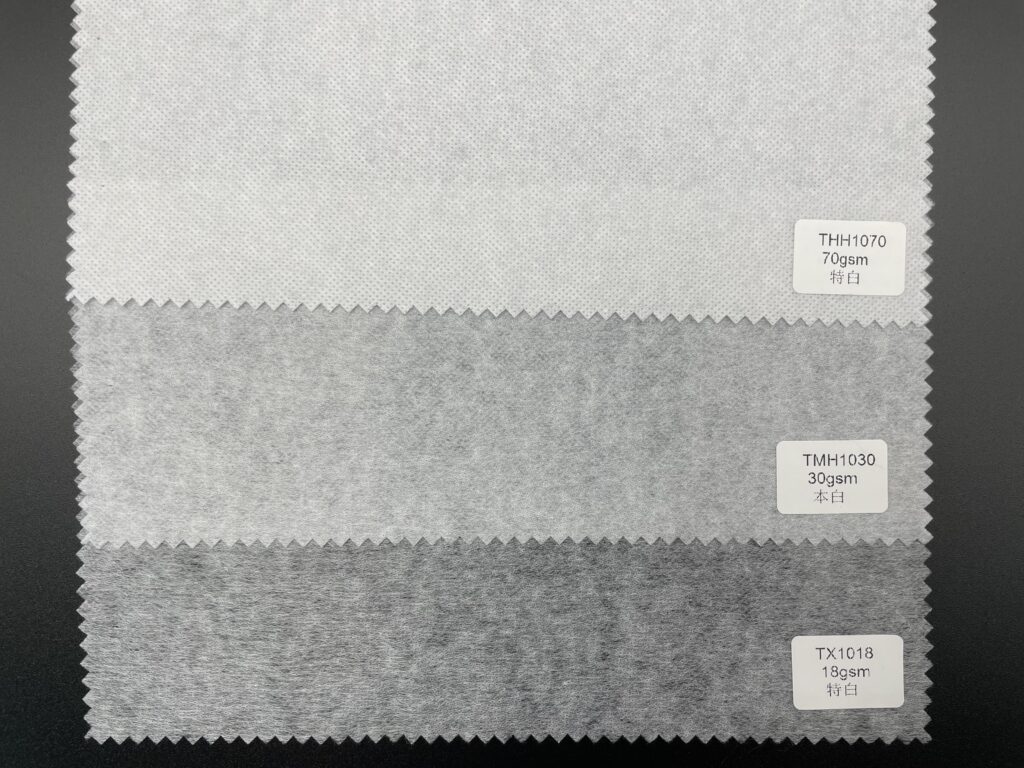

What is GSM in non-woven fabric?

You see "GSM" on every spec sheet, but what does it really mean? Choosing the wrong number can lead to overspending on material that’s too heavy or product failure from fabric that’s too weak.

GSM stands for Grams per Square Meter. It is a standard measurement of a fabric's weight and density. A higher GSM number means a heavier and thicker fabric, while a lower GSM number means a lighter and thinner fabric.

GSM is more than just a number on a technical data sheet. It's one of the most fundamental specifications that tells you about the fabric's potential performance and cost. But to use this number effectively, you need to understand how it's measured and what it really means for your specific product. Let’s explore why this simple metric is so important.

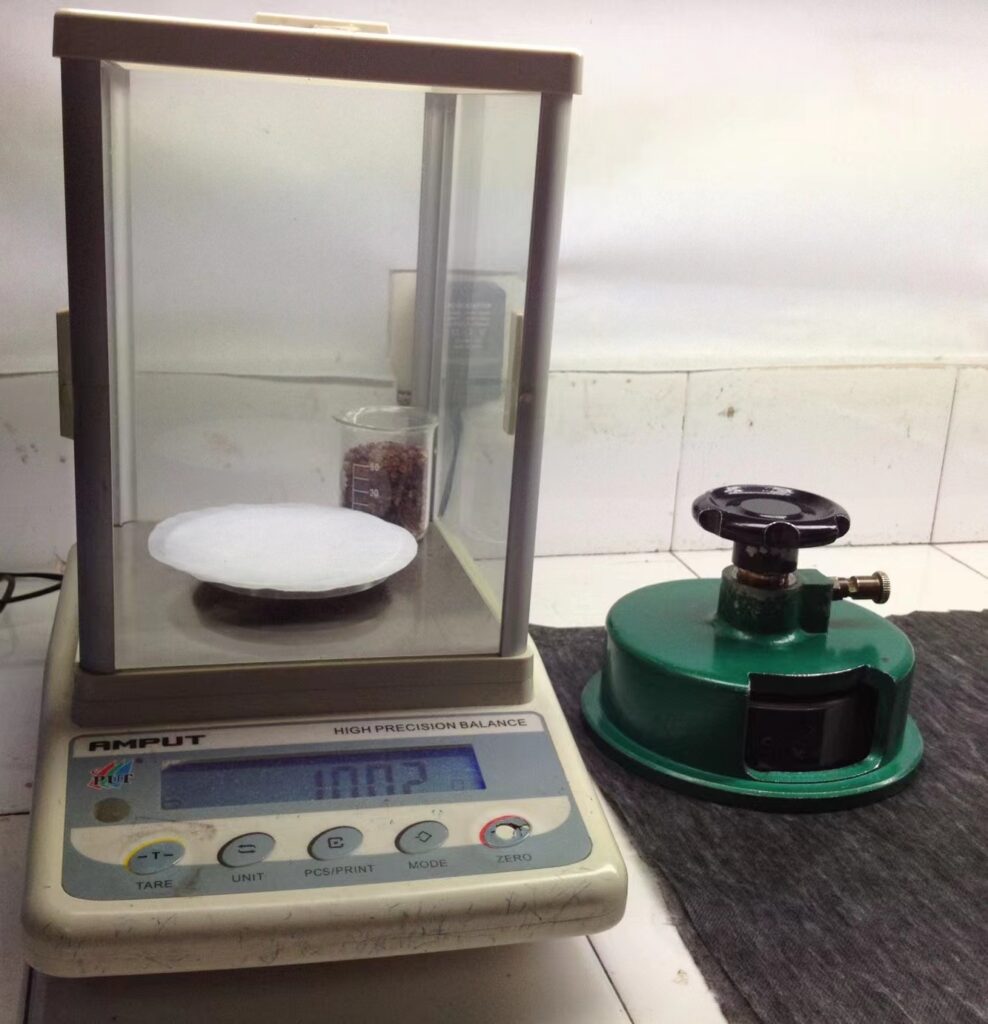

How do you check the GSM of nonwoven fabric?

Your new fabric roll feels lighter than you ordered, and you're worried it won't perform. Without a way to check, you risk production issues and are not sure if you got what you paid for.

To check GSM, cut a precise 1-meter by 1-meter square of fabric and weigh it in grams. The resulting weight is its GSM. For a smaller piece, use a special GSM cutter to get a 100cm² sample, weigh it, and multiply that number by 100.

Verifying the GSM of a fabric you receive is a basic but critical quality control step. It ensures you are getting the material you specified and that it will perform as expected in your machines and for your final product. I've always believed that our customers should feel empowered, and knowing how to do this simple test is part of that. However, at Golden Lily, we don't just rely on final checks. We believe quality has to be built into every step of the process.

The Manual vs. The Professional Method

You can perform this test in two main ways.

| Method | Process | Best For |

|---|---|---|

| Basic Method | 1. Carefully measure and cut a 1m x 1m square. 2. Place it on a precise digital scale. 3. The weight shown in grams is the GSM. | Quick checks with a large piece of fabric, no special tools needed. |

| Professional Method | 1. Place fabric on a cutting mat. 2. Press a circular GSM cutter down and turn it to cut a perfect 100cm² circle. 3. Weigh the circle in grams. 4. Multiply the weight by 100. | Highly accurate results, the industry standard for quality control labs. |

Why We Focus on In-Process Control

While these manual tests are useful for verification, they only tell you the GSM of one small spot. True quality lies in uniformity across the entire roll. That’s why our advanced production lines have online systems that constantly measure the fabric's weight as it's being made. If the system detects even a slight deviation, it automatically adjusts the process in real-time. This continuous monitoring is how we guarantee that the GSM is consistent from the first meter to the last. It’s a core part of how we ensure our customers receive a truly uniform product.

What is a good GSM for fabric?

You want to buy the best quality, so you assume a higher GSM fabric is always better. But this common mistake can lead you to over-engineer your product and waste a lot of money.

There is no single "good" GSM, because the right GSM depends entirely on the product's application. A good GSM is one that perfectly matches the strength, weight, and breathability requirements for the end use.

Over my two decades in this business, I’ve seen people make this mistake many times. They believe "heavier is stronger, so heavier must be better." But that is not true. In fact, some of our most technologically advanced products are extremely lightweight. I always tell my team and my customers that we should not use GSM to judge whether a fabric is good or bad. Quality is about meeting the specification perfectly, not about being high or low on a scale. A high-quality 15 GSM fabric for a tea bag is just as impressive as a high-quality 150 GSM fabric for an industrial application.

Matching GSM to Application

The most important step is to match the fabric's weight to its job. A fabric that is perfect for one product would be a complete failure in another. Here is a simple guide to show how different applications require different GSM ranges.

| Application | Typical GSM Range | Why this GSM works |

|---|---|---|

| Tea Bags / Coffee Pods | 12 - 20 GSM | Must be very light and porous to allow water to flow through freely. |

| Face Masks / Medical Gowns | 16 - 45 GSM | Balances breathability for comfort with a dense enough structure for filtration. |

| Interlinings for Apparel | 18 - 60 GSM | Provides structure and support to garments without adding excessive bulk or weight. |

| Wet Wipes / Cleaning Cloths | 40 - 80 GSM | Needs enough body and strength to hold liquid and withstand scrubbing. |

| Geotextiles / Insulation | 80 - 200+ GSM | Requires high strength and durability for demanding construction or industrial uses. |

As you can see, a "good" GSM is relative. Using a 100 GSM fabric for a tea bag would be a disaster—it would be too thick for water to infuse properly. Using a 15 GSM fabric for an industrial wipe would be equally terrible, as it would fall apart immediately. The key is to define your need first, then select the appropriate GSM.

Conclusion

GSM measures fabric weight, not its quality. The "best" GSM is the one that fits your product's specific needs, and true quality lies in the uniformity of that weight.

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.