What is laminated non-woven?

A single layer of fabric often can't do everything. You might need something that is both soft and waterproof, or both strong and able to filter tiny particles.

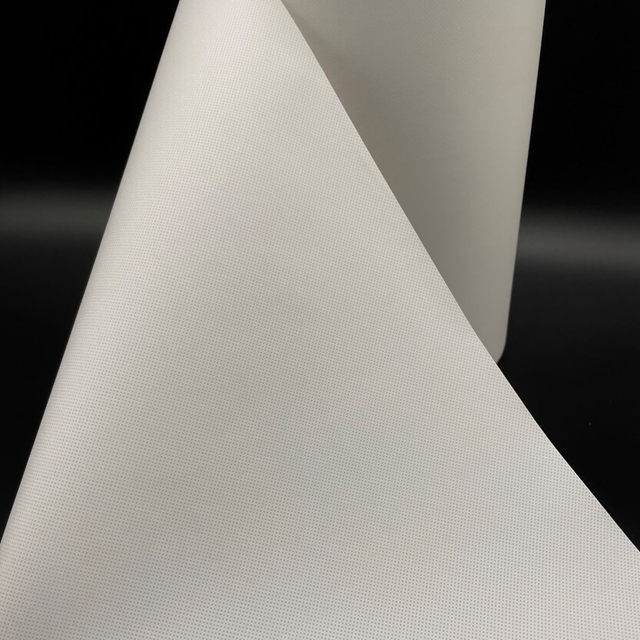

A laminated non-woven is a composite material created by bonding two or more fabric layers together. This process combines the properties of different materials, like the softness of a non-woven with the waterproof barrier of a film, to create a new, multifunctional fabric.

In my years of producing non-woven fabrics, I have seen that the biggest innovations come from combining materials. A simple polyester non-woven is useful, but its true potential is unlocked when you pair it with something else. It is like baking a cake. Flour is essential, but it is not a cake until you add eggs, sugar, and milk. Lamination is the process of combining these "ingredients" to create a final material that is far more capable than any of its individual parts. It allows us to engineer fabrics for very specific and demanding jobs.

How to make laminated non-woven fabric?

You understand the concept of layering fabrics, but how do you actually stick them together? Simply sewing or gluing them can be messy, weak, or completely ruin the fabric's properties.

Laminated non-wovens are typically made using thermal bonding, ultrasonic bonding, or adhesive lamination. The chosen method depends on the materials being combined and the desired characteristics like softness, strength, or breathability for the final product.

The secret to a good laminated fabric is creating a strong bond without compromising the function of the layers. We can't just slap some glue on it, especially for products used in hygiene or filtration. The process must be precise and clean. Here are the main ways it's done:

Common Lamination Methods

- Thermal Lamination: This is one of the cleanest methods. In this process, the layers are passed through large heated rollers. Either one of the layers has a lower melting point, or a thin web of low-melt binder fiber is placed between them. The heat and pressure fuse the layers together permanently. This is a great method for food-grade or medical products because it involves no chemicals.

- Ultrasonic Lamination: Instead of overall heat, this method uses high-frequency vibrations. The vibrations generate intense, localized heat at specific points, melting and welding the thermoplastic fibers of the layers together in a distinct pattern. This creates a strong bond without making the entire fabric stiff.

- Adhesive Lamination: This method involves applying a specialized adhesive between the layers before they are pressed together. This can be a sprayed-on liquid glue or, more commonly, a hot-melt adhesive that is heated to bond the layers. The key is to use an adhesive that doesn't interfere with the final product's function, like blocking the pores of a breathable film.

| Method | How it Works | Best For |

|---|---|---|

| Thermal | Heat and pressure fuse fibers | Hygiene products, filtration |

| Ultrasonic | Vibrations create pinpoint welds | Medical gowns, quilting |

| Adhesive | Glue layer bonds the materials | Industrial composites, durable goods |

What are the properties of laminated non-woven fabric?

A standard fabric can't be both waterproof and breathable. It can't be both a delicate filter and a strong structural support. This limits its use in today's advanced products.

Laminated non-wovens achieve functions that single-layer fabrics cannot. By combining materials, they can be waterproof yet breathable, offer superior filtration, or provide dramatically enhanced strength, opening them up to a wider range of applications.

Lamination is all about creating a new material that is greater than the sum of its parts. I have worked with countless clients to create composite fabrics that solve a specific problem. It is about taking the best feature from two different materials and putting them together in one fabric.

Creating New Functions

- Waterproof and Breathable: A common example is laminating a soft non-woven fabric to a microporous PE film. The non-woven provides a comfortable, skin-friendly layer, while the film provides the function. The film has microscopic pores that are too small for liquid water to pass through but large enough for water vapor (like sweat) to escape. This is the technology behind disposable medical gowns, mattress protectors, and roofing membranes.

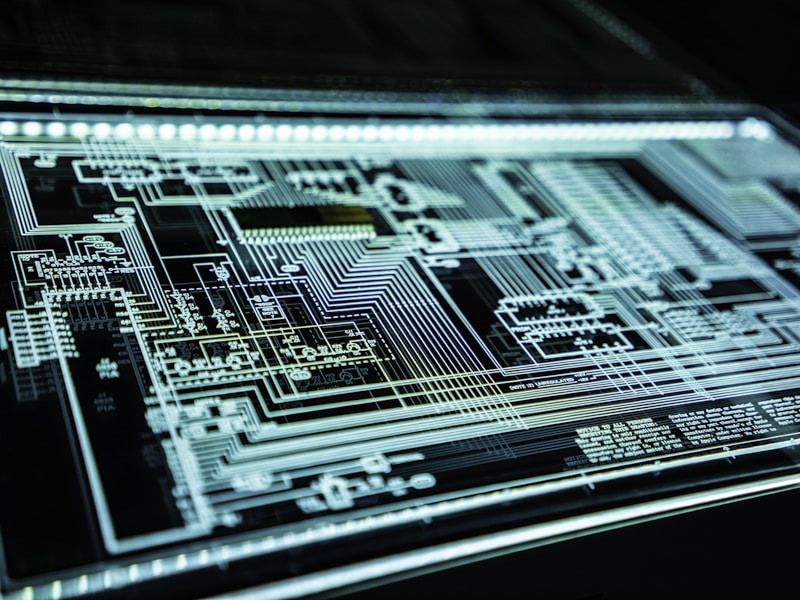

- High-Performance Filtration: This is an area my company specializes in. We laminate our stiff polyester support fabric to a layer of meltblown fabric. The meltblown web is amazing at trapping fine particles but is very fragile. Our support fabric gives it the structure to be pleated and used in things like HEPA air filters or the single-serve coffee filter bags my customer uses. The lamination creates a filter that is both strong and highly efficient.

- Enhanced Strength and Durability: Sometimes, you just need a tougher fabric. By laminating two layers of spunbond non-woven together (known as SS fabric), you can create a material with much higher tensile and tear strength than a single layer of the same weight. This is often used for reusable shopping bags, agricultural fabrics, and industrial packaging.

Conclusion

Laminated non-wovens bond multiple layers to create high-performance materials. This process creates new functions like waterproofing or advanced filtration that a single fabric layer could never achieve alone.

Related Articles

Hello world!

Welcome to WordPress. This is your first post. Edit or

How do you choose the right thermal bonding nonwoven fabric?

Choosing the wrong nonwoven material is a costly mistake. This

How non-woven fabric become water resistance

Non-woven fabrics are naturally quite absorbent due to their structure

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.