What is nonwoven paper?

The name "nonwoven paper" is confusing. You hear "paper" and think of wood pulp, a material that tears easily and falls apart when wet. This can cause you to overlook a very useful material.

Nonwoven paper is not traditional paper. It is a type of non-woven fabric, typically made from synthetic fibers, that is engineered to look and feel like paper. It offers the appearance of paper but with far superior strength, tear resistance, and durability.

This is one of the most common questions I get at trade shows. People will pick up a sample of our fabric, feel its smooth, paper-like surface, and ask, "Is this paper?" I always enjoy this question because it opens the door to explaining how we can engineer fabrics to have specific, unique properties. We can create a material that looks like one thing but performs on a completely different level. It's a perfect example of how versatile non-woven technology truly is.

How is nonwoven paper different from real paper?

You need a material for your packaging or label, but regular paper isn't strong enough. It rips during handling and can be easily damaged, making your product look cheap and unreliable.

Nonwoven paper is different from real paper in its material, manufacturing, and performance. It uses synthetic fibers instead of wood pulp, is bonded by heat instead of pressed from a slurry, and is much stronger, tear-resistant, and more durable, especially when wet.

The differences are fundamental, starting from the very beginning of the production line. While the end products might look similar from a distance, their internal structure and capabilities are worlds apart. This is why nonwoven paper can succeed in applications where traditional paper would fail.

Material and Manufacturing

Traditional paper is made from cellulose fibers, usually from wood pulp. These short fibers are mixed with water to form a slurry, which is then spread, pressed, and dried. The fibers are held together by a natural bond called hydrogen bonding, which is very weak, especially when it gets wet.

Nonwoven paper, on the other hand, is most often made from synthetic staple fibers like polyester (PET). Instead of a wet slurry, we use a dry process. The fibers are combed into a flat web and then fused together with heat and pressure. The bond is a physical melting and re-solidifying of the fibers, which is much stronger and permanent.

Performance and Durability

This difference in manufacturing leads to a huge gap in performance. Paper has low tensile strength and tears very easily along a straight line. Nonwoven paper has fibers going in multiple directions, distributing stress and making it incredibly difficult to tear. It also maintains its strength when wet, whereas paper loses almost all its integrity.

| Feature | Traditional Paper | Nonwoven Paper |

|---|---|---|

| Raw Material | Wood Pulp (Cellulose) | Synthetic Fibers (e.g., Polyester) |

| Bonding Method | Hydrogen Bonds (Weak) | Thermal Fusion (Strong) |

| Tear Resistance | Low | Very High |

| Wet Strength | Very Low | High |

| Durability | Low | High |

How is nonwoven paper made?

You understand that nonwoven paper is a fabric, not paper. But how do you create a non-woven fabric that successfully mimics the smooth, uniform appearance of high-quality paper?

The most common method is wet-laying, which uses water to distribute fibers like in papermaking. However, a paper-like finish can also be achieved through a dry-laid thermal bonding process, where fine fibers are combed into a web and then fused by heated rollers.

While the industry often uses the wet-laid process1 because it’s so similar to actual papermaking, my company has perfected the thermal bonding method to achieve a similar result. In fact, one of the most well-known "papers" in the desiccant industry is made this way.

The Thermal Bonding Method

Many of our customers use our fabric for desiccant packets, the kind you find in shoe boxes or electronics packaging. The material they use is often called "Aihua Paper," but it isn't paper at all—it's our thermally bonded polyester non-woven.

Here's how we make it:

- Fiber Selection: We start with very fine polyester staple fibers. The fineness of the fiber is key to achieving a smooth, non-porous surface.

- Carding: The fibers are carefully opened and run through a carding machine. This process combs the fibers into a very even and consistent web. Any inconsistency here would show up in the final product.

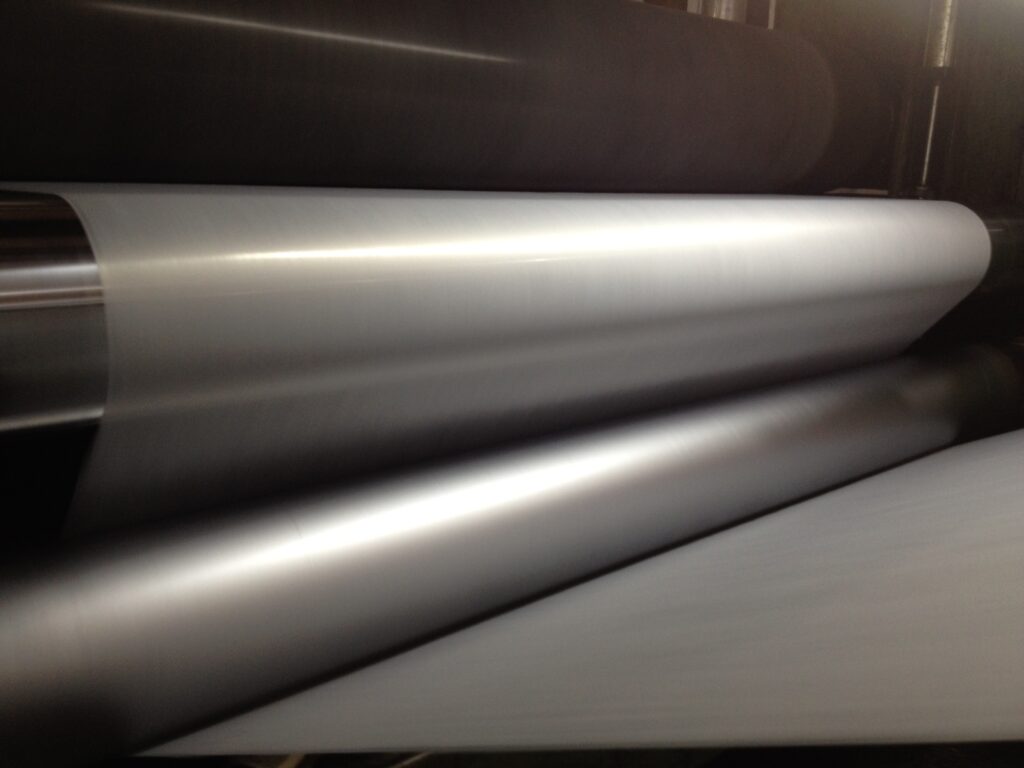

- Hot Rolling (Calendering): The web is then passed between large, smooth, heated steel rollers. The intense pressure and heat do two things: they fuse the polyester fibers together to create a strong sheet, and they press the surface flat, giving it that characteristic smooth, paper-like finish.

By controlling the fiber size, web consistency, and the temperature and pressure of the rollers, we can create a fabric that is often mistaken for paper, but is much, much stronger.

Conclusion

Nonwoven paper is a durable fabric designed to look like paper. Made from synthetic fibers fused by heat, it offers superior strength and tear resistance compared to traditional wood pulp paper.

-

Learn about the wet-laid process, its significance in the industry, and how it compares to other methods. ↩

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.