What is nonwoven polyester?

You constantly hear about polyester, but what is nonwoven polyester, really? If you don't know the difference, you might choose a material that can't handle the heat or lacks the strength your product needs.

Nonwoven polyester is a fabric-like material made from polyester fibers bonded together by heat, chemicals, or mechanical entanglement, not by weaving or knitting. It is known for its exceptional strength, stability, and resistance to heat and chemicals.

Polyester is one of the most reliable and versatile materials we work with at Golden Lily. Its unique properties make it the perfect choice for a huge range of demanding applications, from nonwoven interlining to insulation materials. But to really appreciate why it's so useful, we need to start with the basic building block of the fabric itself.

What is a polyester fiber?

You know polyester is a type of plastic, but how does a plastic pellet become a fiber? Understanding this process is key, as it defines the fabric's final performance characteristics.

A polyester fiber is a synthetic fiber extruded from a polymer called PET, the same plastic used in water bottles. The plastic is melted and forced through a spinneret, which has tiny holes, to form continuous filaments that are then cooled.

The journey from a simple plastic chip to a high-performance fiber is a process we have perfected over many years. It's a bit like making spaghetti. You start with your raw material—in this case, PET chips—and you melt it down to a consistent, honey-like liquid. This molten polymer is then pushed through a device that looks like a showerhead, called a spinneret. As the liquid polymer shoots out of the tiny holes, it immediately cools and solidifies into long, continuous strands. These strands are called filaments.

From Filament to Fabric

Once we have these filaments, a whole new set of possibilities opens up. The fibers can be used in two main forms, and this choice is critical for the final fabric.

| Fiber Type | Description | How It's Used in Nonwovens |

|---|---|---|

| Filament | The long, continuous strands that come directly from the spinneret. Can be miles long. | Used to make spunbond fabrics. The filaments are laid down on a belt and bonded together to create strong, sheet-like materials. |

| Staple Fiber | Filaments are cut into short, predetermined lengths, from a few centimeters to several inches. | Used in processes like thermal bonding, needle-punching, or spunlace. These shorter fibers are spread into a web and then bonded. |

At Golden Lily, we have a deep expertise in working with short staple fibers for our thermal bonded fabrics. We specify the exact length and thickness (denier) of the fibers we need. This control allows us to create materials like our heat-sealable nonwovens for tea bags and coffee pods, where the fabric needs to be both porous and strong when sealed.

What are the characteristics of polyester non-woven fabrics?

You might think polyester nonwoven is just a strong plastic sheet. But if you overlook its other key features, you could miss out on a material that perfectly solves your specific manufacturing challenge.

Polyester nonwovens are highly valued for their superior strength, dimensional stability, and resistance to high temperatures, chemicals, and UV light. They are also hydrophobic, meaning they resist moisture, and hold their shape exceptionally well under stress.

One of my core beliefs is that we must enable every member of our team to "work happily and live a dignified life." A big part of that is giving them the best materials to work with. Polyester is one of those materials. Its reliability and consistent performance mean fewer production issues for our team and a better, more dependable product for our customers. When a material is this stable and predictable, it creates a less stressful and more successful environment for everyone. This reliability is built on a foundation of several key characteristics.

A Breakdown of Key Properties

| Characteristic | Description | Why It's Important for Applications |

|---|---|---|

| High Strength | Polyester fibers are inherently strong and resistant to tearing or stretching. | Essential for industrial applications like filters, geotextiles, and packaging that must withstand physical stress. |

| Dimensional Stability | The fabric does not easily shrink or stretch with changes in temperature or humidity. | Critical for products like honeycomb shades or pleatable filter media that must maintain a precise shape and size over time. |

| High-Temperature Resistance | It has a higher melting point (~260°C) than many other common polymers like polypropylene. | Perfect for DMD electrical insulation, hot-fill liquid filters, and heat-sealable packaging like tea bags. |

| Chemical & UV Resistance | It holds up well against many acids, solvents, and other chemicals, and degrades slowly in sunlight. | Makes it ideal for outdoor use in construction (geotextiles) or in applications with chemical exposure. |

These properties combined make polyester nonwoven a true workhorse material for many industries.

What are the applications of polyester nonwoven fabrics?

You understand the properties, but where is polyester nonwoven actually used? It's in more products than you realize, and your next big product innovation might depend on it.

Polyester nonwovens are widely used in industrial filtration, electrical insulation, specialty packaging, furniture, apparel interlinings, and automotive components. Its unique combination of strength and resistance makes it a preferred choice for many demanding applications.

Our customer base at Golden Lily is a perfect reflection of polyester's versatility. We supply manufacturers of honeycomb shades who rely on its dimensional stability. We partner with producers of DMD insulation materials who need its high-temperature resistance. We provide solutions for makers of air filters and even self-absorbing ice packs. Each customer has a different challenge, but often polyester nonwoven is the answer. It is our job to understand their world and provide the exact material they need to succeed.

Major Application Areas

Polyester's unique skillset allows it to perform well in many different fields.

### Filtration and Separation

Polyester nonwovens are a backbone of the filtration industry. They are used as a support layer in air filtration composite materials, giving strength to the more delicate filter media. They are also used directly for liquid filtration in things like coffee filter pods because they are strong, inert, and can handle hot water.

### Packaging Materials

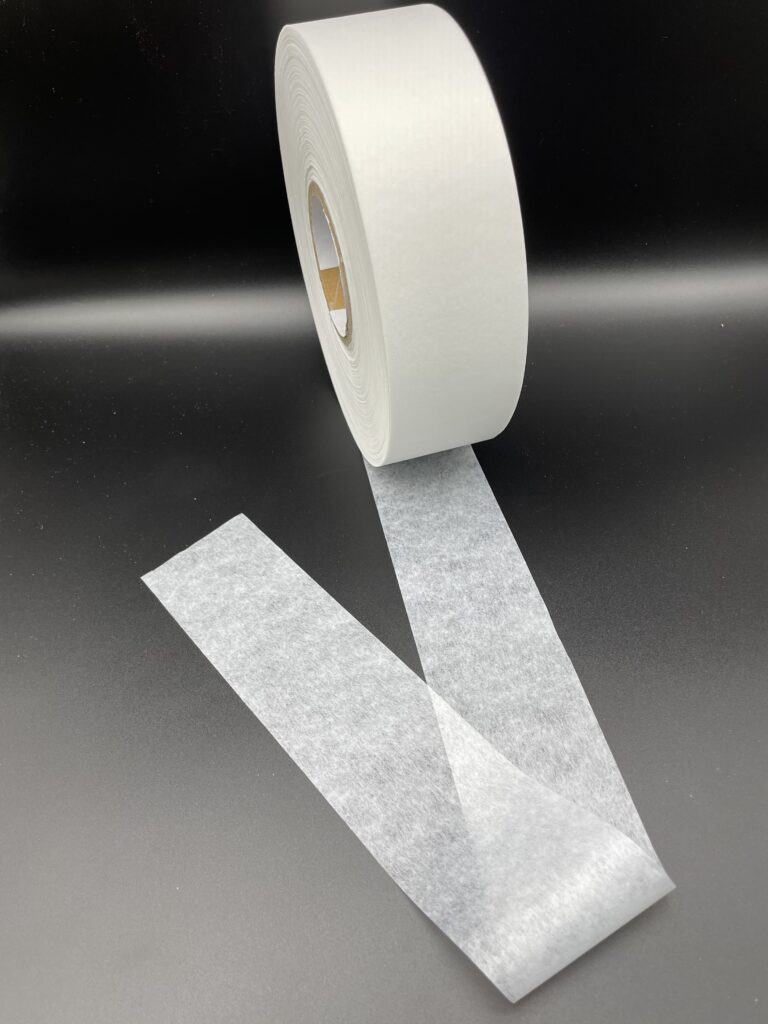

This is an area where our expertise in short-fiber thermal bonded nonwovens really shines. Our fabrics are engineered for the high-speed production of tea bags and desiccant packets. The material is porous, strong, and seals perfectly with heat, keeping the contents secure while allowing for infusion or absorption.

### Insulation and Construction

The "D" in DMD (Dacron-Mylar-Dacron) insulation materials stands for a brand name of polyester. Its excellent heat resistance and dielectric properties make it essential for insulating motors and transformers. In construction, its strength and durability make it a go-to for geotextiles used in soil stabilization.

### Furnishings and Apparel

The incredible dimensional stability of polyester nonwoven is why it's the primary material for honeycomb (or cellular) shades. It holds its crisp pleats for years without sagging. It is also widely used as non-woven interlinings to give structure to shirt collars, cuffs, and waistbands.

Conclusion

Nonwoven polyester is a strong, stable, and highly resistant material. Its unique properties make it the hidden hero in countless products, from the tea bag in your cup to critical industrial filters.

Related Articles

Hello world!

Welcome to WordPress. This is your first post. Edit or

How do you choose the right thermal bonding nonwoven fabric?

Choosing the wrong nonwoven material is a costly mistake. This

How non-woven fabric become water resistance

Non-woven fabrics are naturally quite absorbent due to their structure

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.