What is the difference between non-woven and woven?

You see the words "woven" and "non-woven" but they may seem interchangeable. Choosing the wrong one can lead to failures, as your material might not have the right strength, feel, or function.

The core difference is their structure. Woven fabrics are made by interlacing threads at right angles, creating a grid. Non-woven fabrics are made from a web of fibers bonded directly together using heat, chemicals, or pressure, entirely skipping the weaving process.

The names themselves tell the whole story, but it's a detail many people miss. Woven fabric is created on a loom, a process that has been around for thousands of years. Non-wovens are a product of modern industrial technology. In my factory, we don't have looms or spools of yarn. We start with raw fibers and fuse them into a sheet. This fundamental difference in manufacturing is what creates two completely different families of materials, each with its own unique advantages.

How does the structure affect the fabric's performance?

Your material needs to be strong, but you worry it might tear or fray during use. Woven fabrics have predictable strength, but non-wovens offer a different kind of stability that might be better.

A woven fabric's grid gives it high strength along its threads but can unravel and fray at the edges. A non-woven's random fiber web provides uniform strength in all directions and allows for clean-cut edges that do not fray, making it dimensionally stable.

This difference in performance comes directly from how the material is put together. It's a classic engineering trade-off between an organized structure and a random one.

Grid vs. Web

A woven fabric is like a chain-link fence. It has threads running lengthwise (the warp) and threads running crosswise (the weft). These threads are interlaced. This structure is very strong along those two directions but can be easily distorted diagonally. And if you cut it, the threads at the edge can easily come loose and unravel.

A non-woven fabric is more like felt. At my company, we take short staple fibers, comb them into a flat web, and then use heat and pressure to meld them together. The fibers are locked in place in a random orientation. This means the strength is more or less equal no matter which direction you pull it. Because there are no threads to unravel, you can cut it into any shape and the edges will remain clean and stable.

This table breaks it down simply:

| Feature | Woven Fabric | Non-Woven Fabric |

|---|---|---|

| Structure | Organized grid of yarns | Random web of fibers |

| Strength | Directional (strong on grain) | Uniform (isotropic) |

| Edge Finish | Fray easily | Do not fray |

| Drape | Generally good, follows yarn | Can be engineered from stiff to soft |

| Production | Slower, more complex | Faster, more direct process |

Why choose a non-woven fabric over a woven one?

Woven fabrics are traditional and familiar for things like clothing and upholstery. But are they always the best or most cost-effective choice? You might be missing an opportunity for better performance.

Choose a non-woven for applications demanding specific, engineered properties like filtration, sterility, or absorbency, often at a lower cost. Their direct production process is faster and allows for features like clean edges and layered composites that are difficult with wovens.

This is a conversation I have with clients all the time, especially those in technical fields. They come to me because woven fabric isn't solving their problem. Years ago, almost all garment interlinings were woven. Today, our non-woven interlinings are used in countless high-quality jackets. Why? Because we can engineer them to be perfect for the job.

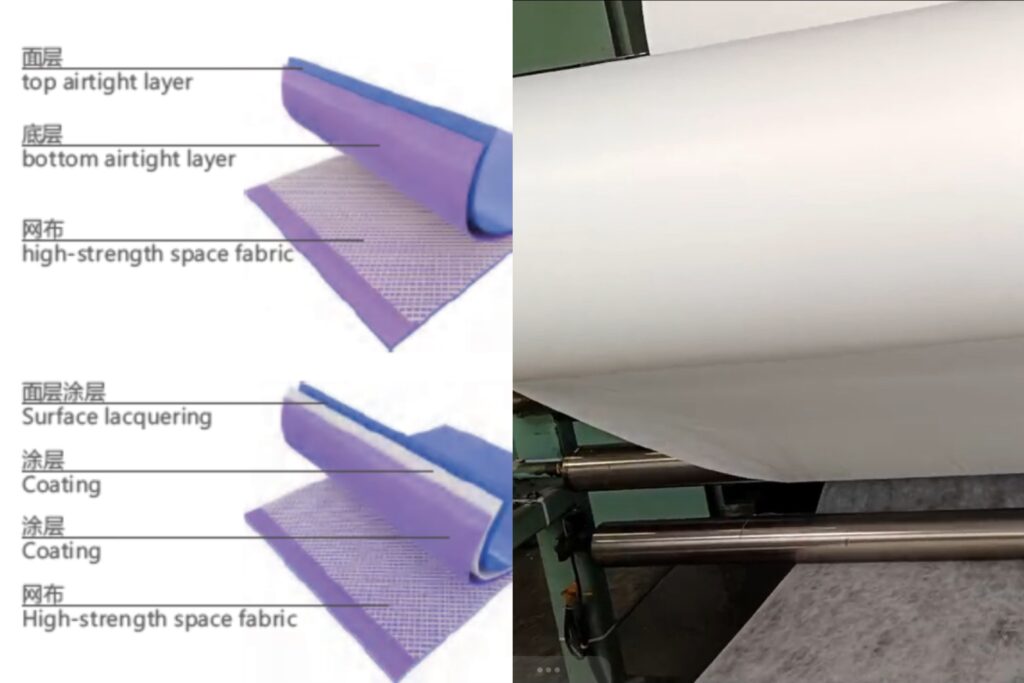

The primary reason to choose a non-woven is "customization." With a woven fabric, you can change the thread and the weave pattern. With a non-woven, I can change the fiber itself (polyester, nylon, etc.), the fiber thickness, the web density, the bonding method, and apply special finishes. This gives us an incredible amount of control. For example, for an air filtration client, we created a stiff polyester non-woven that provides structural support. For a packaging client, we made a heat-sealable non-woven that is safe for food contact. Neither of these could be easily or cheaply made with a woven process. The speed and efficiency of non-woven production also mean we can often deliver these highly customized solutions at a very competitive price point.

Can non-wovens replace woven fabrics?

You need a material with the feel and drape of a woven textile, but require the benefits of a non-woven, like no-fray edges. This seems like a contradiction, making you think you have to compromise.

Yes, in many applications, high-quality non-wovens can replace wovens. By carefully selecting fine fibers like polyester or nylon and controlling the bonding process, we can create soft, drapable non-wovens that mimic the feel of traditional textiles while adding superior stability.

This is where my experience with fibers becomes so important. The perception of non-wovens is often that they are stiff and paper-like, like the material in a disposable bag. But that is just one type. We can achieve a huge range of textures.

One of our main product lines is garment interlinings. Originally, this market was dominated by woven fabrics. To break in, we had to create a non-woven that felt and performed just as well, if not better. We achieved this by using very fine staple fibers, sometimes blending polyester with nylon for extra softness and resilience. Our thermal bonding process uses specialized rollers with specific patterns. Instead of fusing the entire surface, we bond it at thousands of tiny points. This bonds the fibers securely but leaves the areas in between soft and flexible, allowing the fabric to drape beautifully. The result is an interlining that gives a garment structure without making it stiff. Plus, manufacturers love it because they can cut it in any direction without worrying about fraying, which saves time and reduces waste. It's a perfect example of a non-woven not just replacing a woven, but improving upon it.

Conclusion

The difference between woven and non-woven lies in their structure: woven is a grid of threads, while non-woven is a bonded web of fibers, offering unique and customizable performance benefits.

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.