What is the raw material for non-woven fabric?

You see "non-woven" on products from face masks to shopping bags, but what are they actually made of? Without knowing this, choosing the right material for your needs is just guesswork.

The primary raw materials for non-woven fabrics are fibers. These can be natural fibers like cotton, but more commonly they are manufactured synthetic fibers, such as polyester (PET) and polypropylene (PP). The specific fiber used determines the fabric\'s final characteristics, like its strength and softness.

In my decades in this industry, from starting in a chemical fiber factory to founding my own non-woven company, everything has always come back to the fiber. It is the fundamental building block. Understanding the raw material is the first and most important step in creating a fabric that performs exactly as you need it to. Choosing the right fiber is like choosing the right type of steel for a construction project; get it wrong, and the entire structure is compromised.

What types of fibers are used in non-woven fabrics?

You hear acronyms like PET, PP, and PLA, but they just seem like a confusing code. This makes it impossible to communicate your needs clearly or to understand a supplier\'s specifications.

Fibers are broadly divided into natural (cotton, wood pulp) and manufactured. Manufactured fibers, like polyester (PET), polypropylene (PP), and nylon, are the most common in non-wovens due to their consistency, versatility, and specific performance characteristics like strength and chemical resistance.

The choice of fiber is the most critical decision in designing a non-woven fabric. Each one brings a unique set of properties to the table. In my factory, we work with a select range of high-quality synthetic fibers because they give us precise control over the final product. Here\'s a simple breakdown of the main categories:

- Natural Fibers: These come from plants or animals. Cotton is soft and absorbent, making it good for wipes. Wood pulp is used in some wet-laid non-wovens for its paper-like qualities. However, their quality can be inconsistent, and they are often more expensive for technical applications.

- Manufactured Fibers: This is where most modern innovation happens. These fibers are created through chemical processes.

- Polyester (PET): This is the workhorse of our industry. It is strong, stable at high temperatures, and resists stretching or shrinking. We use it for everything from filtration support to durable garment interlinings.

- Polypropylene (PP): This fiber is lightweight, water-repellent, and relatively low-cost. It\'s often used for hygiene products and disposable items.

- Nylon (Polyamide): Nylon is the premium option. It\'s incredibly strong, abrasion-resistant, and has a very soft feel, making it perfect for high-end interlinings.

- PLA (Polylactic Acid): This is a bioplastic made from plant starches. It\'s a key material for customers looking for a biodegradable option.

| --- | ||||||

|---|---|---|---|---|---|---|

| Polyester (PET) | Strength, Heat Resistance, Stability | Filtration, Interlinings, Cable Wrap | ||||

| Polypropylene (PP) | Water Repellent, Lightweight, Low Cost | Hygiene, Medical Gowns, Packaging | ||||

| Nylon (PA) | Extreme Softness, High Strength, Abrasion Resistance | High-End Garment Interlinings | ||||

| PLA | Biodegradable, Made from Renewables | Eco-Friendly Wipes, Food Packaging |

Staple fibers or filaments: what’s the difference?

You see terms like "spunbond" and "staple fiber" on data sheets, but what do they mean for your fabric? Choosing the wrong one can result in a material that is too stiff or not strong enough for your product.

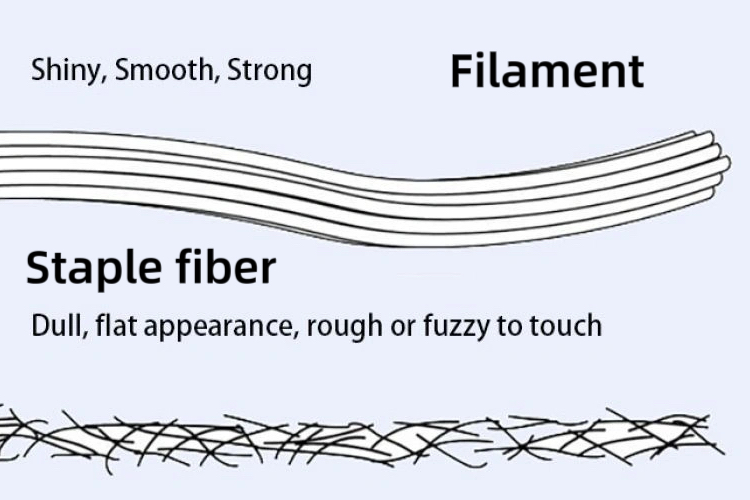

The difference is fiber length. Staple fibers are short, pre-cut fibers (a few inches long) that create soft, lofty, textile-like fabrics. Filaments are single, continuous strands that produce stronger, sheet-like materials such as spunbond non-wovens.

This is a critical distinction that directly impacts the manufacturing process and the final fabric\'s feel and function. My company, Golden Lily, focuses exclusively on using staple fibers. This specialization allows us to master the art of creating soft, uniform fabrics with a specific texture.

Think of it this way:

- Filaments are like spaghetti. They are extruded as long, unbroken strands. In the "spunbond" process, these continuous filaments are immediately laid down onto a belt to form a web, which is then bonded. This creates a very strong, stable, and somewhat stiff fabric. Think reusable shopping bags or house wrap.

- Staple Fibers are like chopped spaghetti. These fibers are produced as long strands but are then intentionally cut into short, uniform lengths. To make a fabric, these loose fibers must first be combed into a flat web using a process called "carding." This web of short fibers is then bonded together. The final fabric is generally softer, bulkier, and has more of a traditional textile feel. This is the method we use to make everything from soft interlinings to filtration support media. The random orientation of short fibers provides a different kind of strength and flexibility.

You\'ve chosen a fiber, but now you hear about thermal, chemical, or needlepunch bonding. It seems like another layer of complexity that could lead to a mistake.

The fiber\'s properties, especially its melting point, directly influence the best bonding method. For example, thermoplastic fibers like polyester and polypropylene are ideal for thermal bonding, as they can be fused with heat. Natural fibers like cotton cannot be thermally bonded.

The raw material and the manufacturing process are completely linked. You cannot choose one without considering the other. My company specializes in thermal bonding because it is a clean, precise, and efficient way to process the high-quality thermoplastic fibers we use, like PET and Nylon.

Here’s how they connect:

- Thermal Bonding: This method uses heated rollers to melt and fuse fibers together. It only works with "thermoplastic" fibers—plastics that melt when heated and re-solidify when cooled. Polyester, polypropylene, and nylon are all thermoplastics. This process is great because it requires no chemical glues, making the final fabric pure and suitable for hygiene or food-contact uses.

- Chemical Bonding: This applies a liquid adhesive to the fiber web to glue it together. This can be used with almost any fiber type, including natural fibers like cotton that don\'t melt. However, the added chemicals can change the fabric\'s properties and may not be suitable for all applications.

- Mechanical Bonding (Needlepunch): This method uses barbed needles to physically tangle the fibers together, like making felt. It works with nearly any fiber and creates thick, dense fabrics used for things like geotextiles or automotive carpets.

The fiber\'s melting behavior is the most important factor here. Because we focus on PET, Nylon, and Bicomponent fibers, thermal bonding is our core technology. It allows us to create strong, consistent fabrics without any additives.

Conclusion

Non-woven fabrics are made from fibers, primarily synthetic ones like polyester and polypropylene. The choice of fiber and its length—short staple or long filament—dictates the fabric\'s properties and manufacturing method.

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.