What kind of non-woven fabric is suitable for desiccant bags?

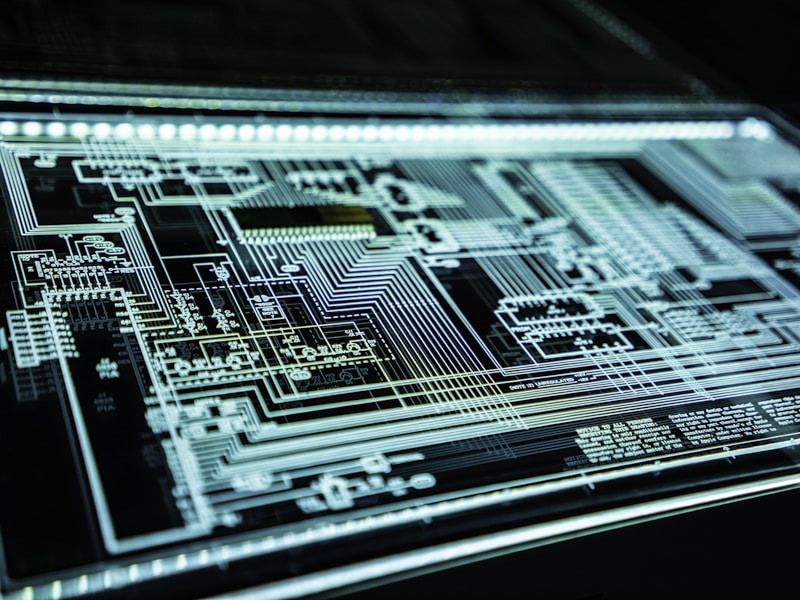

You chose a cheap fabric for your desiccant bags. Now, fine dust is leaking out, contaminating your valuable electronics, and the weak bags are tearing during shipping.

The best nonwoven fabric for desiccant bags must have high breathability, good strength, and excellent dust-proofing. A material like bicomponent thermal bonded nonwoven is ideal because it effectively balances these three critical performance features.

Knowing these three key properties is a good start. But if you can\\'t tell the difference between good and great performance, you might still choose a fabric that fails under pressure. To truly protect your products, we need to dive deeper into what these features mean in the real world and why a specific type of fabric is the best solution.

What are the critical properties for desiccant bag fabric?

You hear terms like "breathability" and "strength," but what do they really mean for a desiccant bag? Choosing based on vague terms can lead to a product that fails.

The critical properties are a precise balance of three things: high air permeability for moisture absorption, strong puncture resistance to contain the desiccant, and a tight fiber structure to block fine dust particles.

I remember working with a client in the pharmaceutical industry. They were using a standard nonwoven for their desiccants, but were experiencing dust contamination in their medicine bottles. The dust particles were tiny, but the risk was enormous. We switched them to one of our specialized nonwovens designed for dust containment. The problem disappeared. This experience taught me that for applications like this, "good enough" is never good enough. The material specifications must be precise. It’s not just about keeping a product dry; it’s about ensuring purity and safety.

Let\\'s break down these essential features into practical terms.

| --- | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Breathability | Allows moisture to pass through and be absorbed by the desiccant quickly and effectively. | A fabric with a high Moisture Vapor Transmission Rate (MVTR) and evenly distributed micropores. | ||||||||

| Strength | Prevents bags from bursting or tearing during automated packaging, shipping, and handling. | Good tensile strength to resist pulling forces and high puncture resistance against sharp desiccant granules. | ||||||||

| Dust-Proofing | Stops tiny desiccant dust particles (0.5-10 microns) from escaping and contaminating sensitive products. | A nonwoven with a dense, uniform fiber structure that acts as a filter, and a smooth surface that doesn\\'t shed its own fibers. |

A failure in any one of these areas renders the desiccant package useless, or even harmful. For example, a fabric can be very strong, but if it\\'s not breathable, the desiccant inside can\\'t do its job. On the other hand, a very breathable fabric that lets dust escape is a major contamination risk for electronics, food, and medicine. The goal is to find a material that delivers excellent performance across all three categories.

Why is a thermal bonded nonwoven a superior choice?

You know the properties you need, but many nonwovens look the same. Choosing the wrong type can mean weak seals, slow production, and a poor-quality final product.

A bicomponent thermal bonded nonwoven is superior because its structure is specifically engineered for this task. It provides strong, clean seals, a dust-free surface, and excellent uniformity, making it a reliable and efficient choice.

At Golden Lily, we have seen firsthand how the right material can transform a customer\\'s production process. A company making desiccant packs for food products was struggling with their old material. Their sealing machines had to run at very high temperatures, which sometimes damaged the fabric and caused the line to stop. We introduced them to our thermal bonded nonwoven1. Because it seals at a lower temperature, they were able to increase their production speed by 15% and dramatically reduce the number of failed bags. This is the power of choosing a material that is truly engineered for the application.

Let\\'s look at why this specific type of fabric works so well.

How Thermal Bonding Works

This fabric is made from special bicomponent fibers. Each fiber has a strong inner core (like PP) and a soft outer sheath with a low melting point (like PE). During production, we pass a web of these fibers through heated rollers. The heat is just enough to melt the outer sheath. This melted material acts like a glue, bonding all the fibers together at their contact points. The strong inner core never melts, so it maintains the fabric\\'s structure and strength.

The Benefits of This Structure

This simple but clever process creates a fabric with unique advantages for desiccant bags.

- Superior Heat-Sealing: Because only the outer layer melts, you get a very strong and consistent seal at a lower temperature. This is perfect for high-speed automated packaging machines. It means fewer burn-throughs, less energy use, and a more reliable seal that won\\'t leak.

- Clean, Lint-Free Surface: The bonding process creates a very smooth and stable surface. The fabric doesn\\'t shed its own fibers (lint), which is another source of contamination. This smooth surface also makes it very effective at trapping fine desiccant dust inside the bag.

- Excellent Printability: A smooth, uniform surface is the perfect canvas for printing. This is very important for branding and for printing critical information like warnings or instructions directly onto the desiccant bag. Clear, sharp printing makes the product look professional and high-quality.

Conclusion

For desiccant bags, choose a nonwoven that expertly balances breathability, strength, and dust control. Bicomponent thermal bonded fabric is a top choice, offering superior sealing, cleanliness, and print quality.

- Explore this link to understand how thermal bonded nonwoven materials can enhance production efficiency and reduce failures. ↩

Related Articles

Hello world!

Welcome to WordPress. This is your first post. Edit or

How do you choose the right thermal bonding nonwoven fabric?

Choosing the wrong nonwoven material is a costly mistake. This

How non-woven fabric become water resistance

Non-woven fabrics are naturally quite absorbent due to their structure

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.