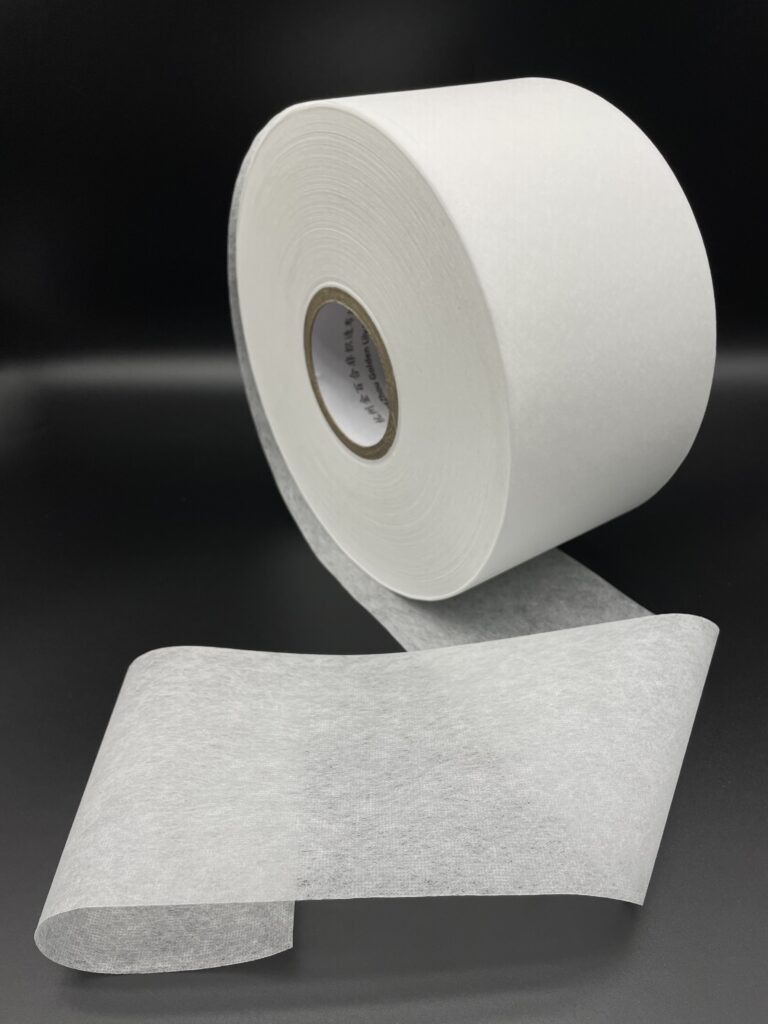

Why does nonwoven fabric get wavy edges?

You’ve received a new roll of nonwoven fabric, but the edges are wavy and rippled. This defect will affect your subsequent processing and may increase consumption.

Nonwoven fabric gets wavy edges primarily because of uneven tension during the winding process. When the center of the roll is tighter than the edges, the loose material on the sides has nowhere to go and forms ripples or waves.

Uneven tension is the biggest culprit, but it\'s not the only one. This problem, which we sometimes call a "lotus leaf edge" in Chinese, can come from several stages of the manufacturing and handling process. To truly prevent this frustrating issue, you need to understand every potential cause. Let’s break them down so you know what to look for and how to avoid it.

What are the main causes of wavy edges?

You see the defect on the roll but don\'t know the real reason. This makes it hard to solve the problem, leading to repeated frustration and production losses.

Wavy edges are caused by a combination of factors, including uneven winding tension, inherent material properties, processing errors during production, and even improper handling during storage and transport.

Over my two decades running Golden Lily, I’ve learned that quality is controlled at every single step. A perfect roll of fabric doesn\'t happen by accident. It’s the result of excellent raw materials, advanced machinery, and highly skilled operators. This is why we invest so heavily in all three. Our production lines are imported, our fibers are top-quality, and our operators are rigorously trained professionals with deep experience. They understand that a tiny error in tension or alignment can ruin a whole batch. Their strict control over the entire process is why the occurrence of wavy edges on our products is extremely low. It’s this attention to detail that separates a good supplier from a great one.

Deep Dive into the Causes

The problem of wavy edges can be traced back to several key areas. Let\'s examine them one by one.

| --- | |||||||

|---|---|---|---|---|---|---|---|

| Winding Process | The roll\\'s center is wound tighter than the edges. The loose edge material buckles and forms waves. | ||||||

| Material Properties | Nonwovens have no woven structure (no warp/weft), making them less dimensionally stable and prone to deforming under stress. | ||||||

| Processing & Slitting | Unstable winding speed, misaligned rollers, or improper stress release during cutting can all create tension imbalances. | ||||||

| Storage & Transport | High humidity can cause uneven shrinking. Stacking rolls incorrectly can put pressure on the edges, causing permanent deformation. |

How a Quality-Focused Process Helps

At Golden Lily, we address these root causes directly.

- Tension Control: Our imported production and slitting lines use advanced sensors to maintain perfectly uniform tension from the center to the edge.

- Process Stability: Our experienced teams ensure every guide roller is perfectly parallel and that winding speeds are constant.

- Material Selection: We start with high-quality fibers that have consistent properties, reducing the chances of inherent material flaws.

By focusing on these fundamentals, we create a product that is flat, uniform, and ready for your production line, saving you time and money.

Conclusion

Wavy edges are a defect caused by issues in tension, processing, and handling. Choosing a supplier with strict quality control from start to finish is the best way to prevent it.

Li Sun

With over 15 years of experience in non-woven fabric manufacturing, I lead our R&D team at Hangzhou Golden Lily. My expertise includes developing innovative filtration materials and sustainable packaging solutions.